Operation (Apollo / Delta 34)

2.1

Startup

Press the key. The startup screen, which shows the software version, will display

for about 8 seconds then the MAIN screen is displayed.

2.2

Selecting the Tank / Product

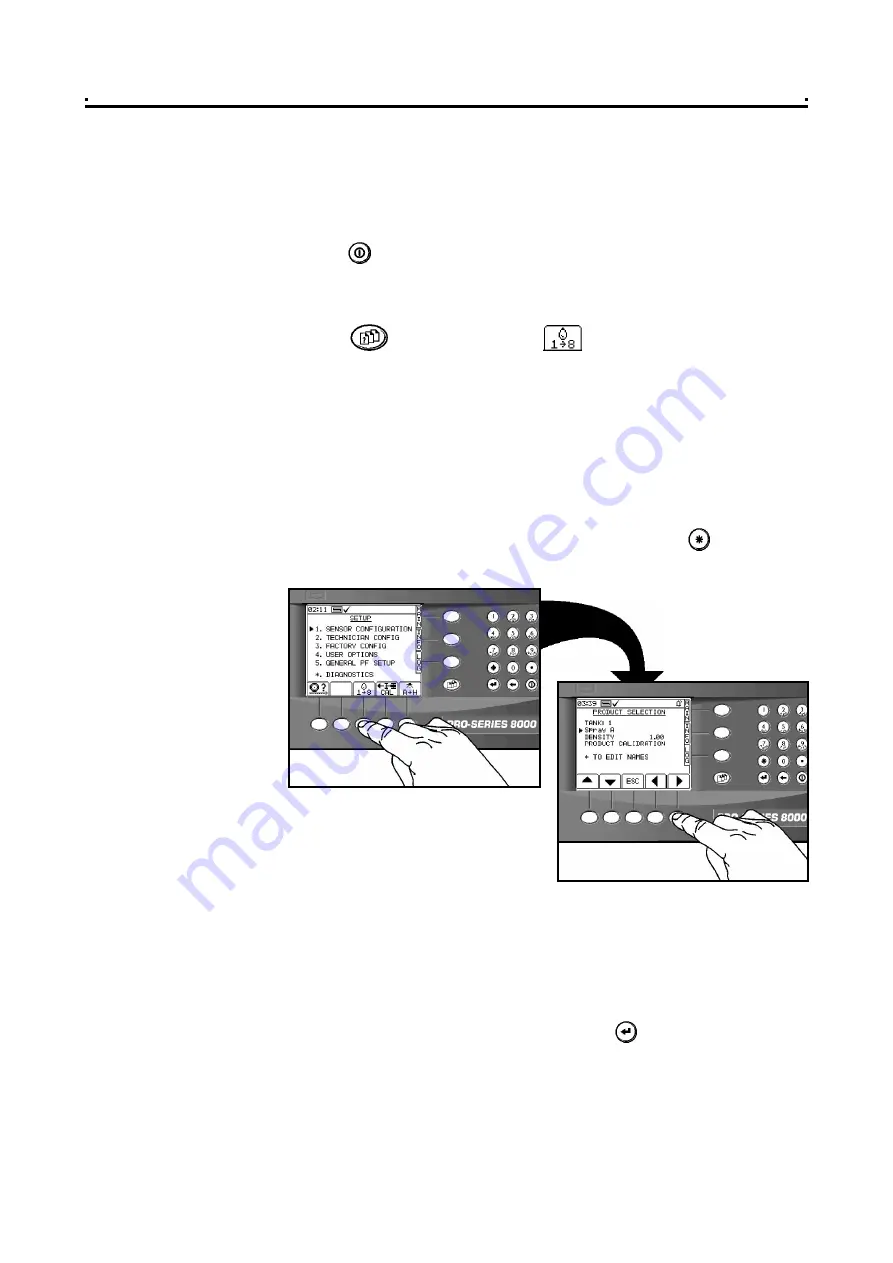

1 Press the key and then press the key (figure 9a).

The 'PRODUCT SELECTION' screen only lists tanks that have been enabled via the

calibration menu.

NOTE 1:

By default, the tanks labelled "Tank 1" to "Tank 4" however, these descriptions may be

edited via the "MACHINE OPTIONS" page in the calibration menu.

2 Select the tank using the left / right arrow key, then using the up / down arrow key,

move the screen cursor opposite the product for that tank (figure 9b). For any tank,

you can programme and calibrate up to 8 different products "A" to "H".

NOTE 2:

By default, the products are labelled "A" for tank 1, "B" for tank 2, "C for tank 3 and "D

for tank 4. You can edit the product description by pressing the key while the

"PRODUCT SELECTION" screen is displayed (section 2.2.1).

3 Press the MAIN key to return to the "MAIN" screen page.

2.2.1

Editing Product Names

The 8 default product descriptions are '

Spray A

' to '

Spray H

'.

From the 'PRODUCT SELECTION' screen, press the key to select the

'PRODUCT NAMES' screen.

Select the product name using the arrow keys, and edit the name using the alpha-

numeric keypad.

2 - Operation

2

Figure 9

Selecting the PRODUCT

SELECTION screen

13