5

All Raypak heaters are National Board registered, and

design-certified and tested by the Canadian Standards

Association (CSA) for the U.S. and Canada. Each heater is

constructed in accordance with Section IV of the American

Society of Mechanical Engineers (ASME) Pressure Vessel

Code, and bears either the ASME “H” stamp for boilers

or “HLW” stamp for water heaters and pool heaters. The

heater also complies with the latest edition of ASHRAE

90.1 Standard.

A

WARNING:

Altering any Raypak pressure vessel

by installing replacement heat exchangers, tube bundle

headers, or any ASME parts not manufactured and/or

approved by Raypak will instantly void the ASME and

CSA ratings of the vessel and any Raypak warranty

on the vessel. Altering the ASME or CSA ratings of the

vessel also violates national, state, and local approval

codes.

Rated inputs are suitable for up to 4,500 ft (1372 m)

elevation without de-rating. Consult the factory for

installations at altitudes over 4,500 ft (1372 m) above sea

level.

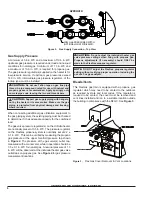

Component Locations

NOTE:

Maintain upright orientation of all components as

shown in Figure 1.

FlexGas cover not shown for clarity

Figure 1. Component Locations – Back

Installation Codes

Installations must follow these codes:

• Local, state, provincial, and national codes, laws,

regulations and ordinances

• National Fuel Gas Code, ANSI Z223.1/NFPA 54 –

latest edition (NFGC)

• National Electrical Code, ANSI/NFPA 70 - latest

edition (NEC)

For Canada only: CAN/CGA B149 Installation Code

(B149.1) and CSA C22.1 C.E.C. Part 1 (C22.1)

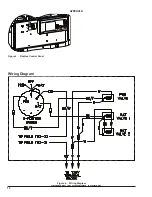

Gas Supply

This heater will be connected to 2 different gas supplies

(Natural Gas and Propane Gas).

Each gas piping must have a separate sediment trap

ahead of the gas controls. Pounds-to-inches regulators

must be installed to reduce the gas supply pressure to

a maximum of 10.5 in. WC for natural gas and 13.0 in.

WC for propane gas. The regulator should be placed a

minimum distance of 10 times the pipe diameter upstream

of the heater gas controls.

A

CAUTION:

The heater must be disconnected from

the gas supply during any pressure testing of the gas

supply system at test pressures in excess of 1/2 psi

(3.45 kPa).

The heater must be isolated from the gas supply piping

system by closing the manual shutoff valves during

any pressure testing of the gas supply piping system

at test pressures equal to or greater than 1/2 psi (3.45

kPa). Relieve test pressure in the gas supply line prior

to reconnecting the heater and its manual shutoff valves

to the gas supply lines.

FAILURE TO FOLLOW THIS

PROCEDURE MAY DAMAGE THE GAS VALVES

. Over-

pressurized gas valves are not covered by warranty. The

heater and its gas connections shall be leak-tested before

placing the appliance in operation. Use soapy water for

leak test. DO NOT use an open flame.

APPROVED

UNCONTROLLED DOCUMENT IF PRINTED