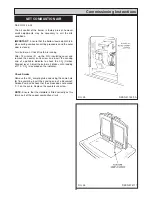

The appliance can only be installed in a room which

meets the ventilation regulations in force. But, in any

event the room must have a permanent vent of minimum

free air area, see below.

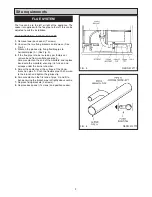

IMPORTANT: THE LOUVRED AIR INTAKE AT THE

BOTTOM FRONT OF THIS APPLIANCE MUST BE

KEPT CLEAR OF ANY OBSTRUCTIONS

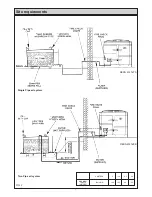

Detailed recommendations for air supply are given in the

Building Regulations, and in BS 5410: Part 1. The

following notes are intended to give general guidance.

1.

Combustion and ventilation air supply to oil fired

appliance has to comply with the Building Regulations

and with BS 5410: Part 1. The air supply requirement for

oil fired appliances is 550mm

2

per kW of maximum rated

output above 5kW. These requirements are illustrated in

OFTEC Technical Book No.3.

2.

The combustion air supply to open flued appliances

should normally be provided at high level into a room

where it will not cause discomfort by creating a cold

draught across the floor.

3.

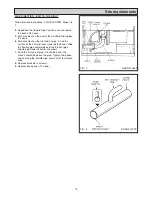

If combustion air is supplied through an under floor

duct the grilles at each end should be positioned in the

vertical plane to reduce the risk of blockage. Ducts should

be sized so as to reduce resistance to air flow.

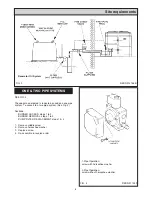

4.

The ventilation requirement for kitchens in Part F of the

Building Regulations is for mechanical extract at the rate

of 60 litres per second or 30 litres per second if the fan is

incorporated in a cooker hood.

Background ventilation is also required, either by

producing a constant mechanical extract rate of one air

change per hour or by having ventilation openings of not

less than 4000mm

2

.

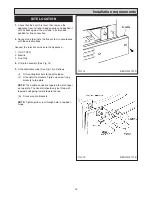

5.

Extract fan should be positioned as far away from the

appliance as possible and should have a sufficient

dedicated air supply. To undertake a test the oil fired

appliance should be set in operation and the doors and

windows of the room containing it should be closed. The

extract fan should then be run at its maximum setting. The

oil fired appliance should be observed to operate

satisfactorily both before and after the fan is switched on.

6.

It is preferable for the air supply for an extract fan to be

located where it can serve the fan without the air stream

passing close to the oil fired appliance.

7.

Oil fired appliances must not draw combustion air from

a garage.

13

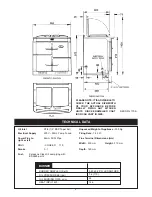

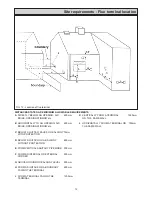

Site requirements

AIR SUPPLY

XT (K P/F)

61 cm

2

MODEL

MIN. AIR REQUIREMENT

AIR SUPPLY

Содержание XT- Oil

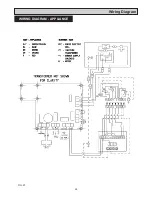

Страница 24: ...24 Wiring Diagram FIG 27 WIRING DIAGRAM APPLIANCE...

Страница 26: ...26...

Страница 27: ...27...