PLEASE READ THESE INSTRUCTIONS BEFORE INSTALLING THIS APPLIANCE

For use in GB and IE

Installation

Instructions

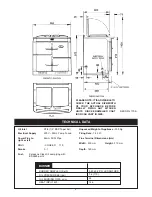

XT - Oil (K P/F)

10/13 EINS 514137

DESN 514112 B

Remember, when replacing a part on this appliance, use only spare parts that you can be assured conform the safety and

performance specification that we require. Do not use reconditioned or copy parts that have not been clearly authorised

by AGA.

Содержание XT- Oil

Страница 24: ...24 Wiring Diagram FIG 27 WIRING DIAGRAM APPLIANCE...

Страница 26: ...26...

Страница 27: ...27...