5

Adequate Combustion And Ventilation Air Options:

• Increase

the

Maximum Supportable Btu/Hr

by adding to the number of rooms which comprise the "Space".

To do this you must ether completely remove the door to an adjoining room or provide two permanent ventilation

grills; one within 12" of the ceiling and another within 12" of the floor.

• Increase

the

Maximum Supportable Btu/Hr

by providing extra fresh air using ventilation grills and ducts to the

outdoors. You must provide two permanent openings, one within 12" of the ceiling and another within 12" of the

floor. Connect these directly to the outdoors or spaces open to the outdoors, e.g., attics or crawl spaces.

• Follow

the

National Fuel Gas Code NFPA 54/ANSI Z223.1, Section 5.3, Air for Combustion and Ventilation

for

required size of ventilation grills or ducts.

• Lower

the

Actual Btu/Hr Used

by relocating other gas burning appliances outside the "space" or installing a

lower Btu/Hr heater. In the example, the maximum Btu/Hr of the heater could be no more than 28,160 Btu/Hr.

For our example, we have chosen to add to our

Total Volume of the Space

by removing the door to an adjoining

study and increasing our

Maximum Supportable Btu/Hr

by the volume of the additional room. The new "space"

calculations, including the additional adjoining room are:

Living room/dining room & Kitchen

3008 cu ft

Study (9' x 10' x 8')

720 cu ft

Total volume of space

3728 cu ft

The new Maximum Supportable Btu/Hr = (3728 cu ft ÷ 50 cu ft ) x 1000 = 74,560 Btu/Hr

74,560

Btu/Hr

=

Maximum

Supportable

Btu/Hr

-

72,000 Btu/Hr = Actual Btu/Hr Used

2,560

Btu/Hr

=

Remaining

Supportable

Btu/Hr

Because the

Actual Btu/Hr

used is now less than the

Maximum Supportable Btu/Hr

, the space is

considered an

Unconfined Space

. No additional fresh combustion and ventilation air would be required.

VENT FREE OPERATION

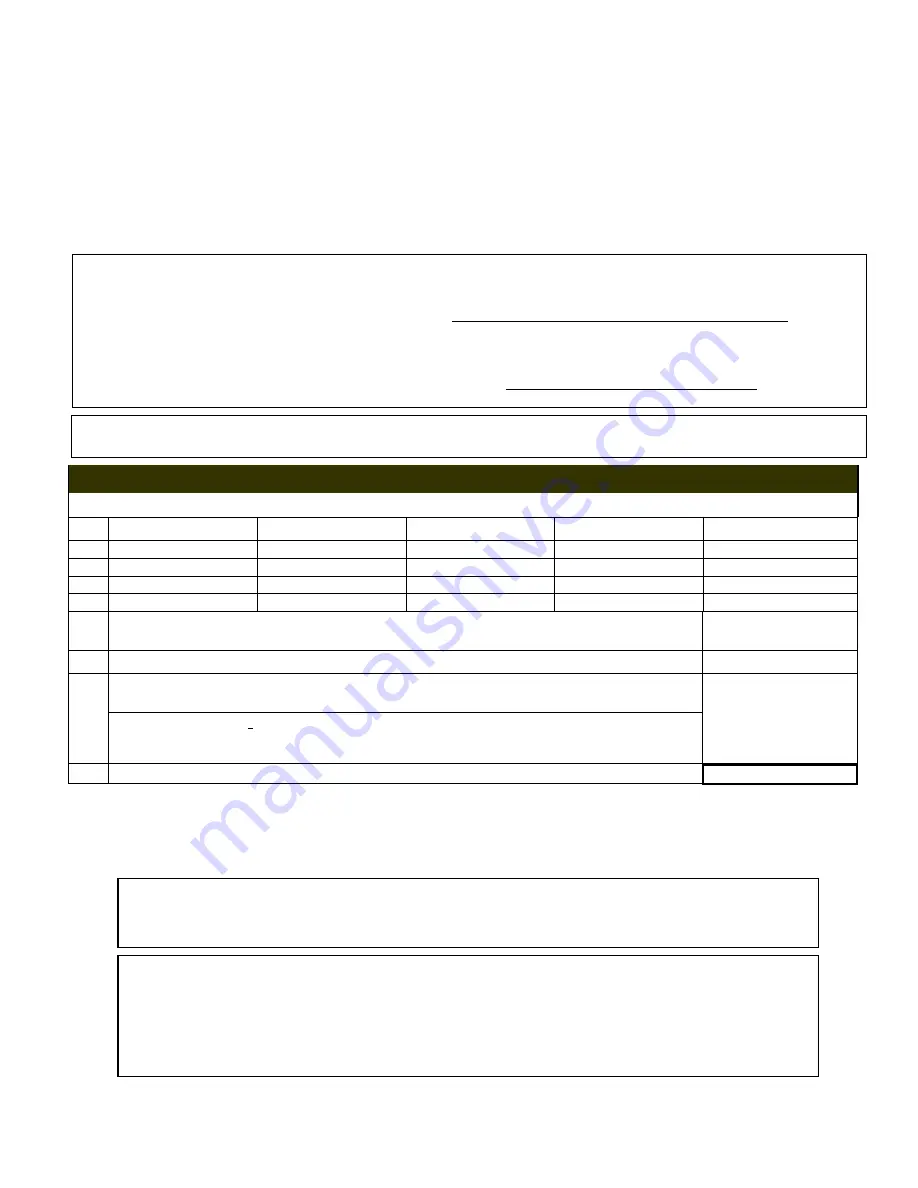

COMBUSTION AIR CALCULATIONS WORKSHEET

1.

Room Width Length Height W

x

L

x

H=Vol. (ft3)

1a.

1b.

1c.

1d.

2. Total Volume (ft3)

sum of Volume (ft3) of all rooms (sum lines 1a. thru

1d.)

2.

3. Max Supportable BTu/Hr

=Total Volume (ft3) ÷ 50 x 1000 (line 2 ÷ 50 x1000)

3.

4. 4a.

3

Btu/hr

4b.

3

Btu/hr

4c.

3

Btu/hr

4d.

3

Btu/hr

Actual Btu/hr used

= Sum Btu/hr of all fuel burning appliances inside the space

identified as rooms 1a. thru 1.b (sum

line 4a thru 4d.)

4.

5. (Maximum Supportable BTu/Hr)

minus

(Actual BTu/hr Used)

(Line 3 - line 4)

5. *

* If

Line

5

is greater than zero, the

Actual BTu/Hr Used

is

less

than the

Maximum Supportable BTu/Hr

and

the space is considered

UNCONFINED

.

No additional fresh combustion and ventilation is required.

* If

Line

5

is zero or less, the

Actual BTu/Hr Used

is

greater

than

Maximum Supportable BTu/Hr

and the

space is

CONFINED.

You must either

increase

the

Maximum Supportable BTu/Hr, decrease

the

Actual

BTu/Hr Used

or

operate as a Vented Appliance

(see page 4).

WARNING: If the area in which the heater may be operated is smaller than that defined as an

unconfined space or if the building is of unusually tight construction, provide adequate

combustion and ventilation air by one of the methods described in the National Fuel Gas Code,

ANSI Z223.1, 1992, Section 5.3 or applicable local codes.

Unusually tight construction is construction where:

a) Walls and ceilings exposed to the outside atmosphere have a continuous water vapor retarder

with a rating of 1 perm or less with openings gasketed or sealed, and

b) Weather stripping has been added on openable windows and doors, and

c) Caulking or sealants are applied to areas such as joints around window and door frames,

between sole plates and floors, between wall panels, at penetrations for plumbing, electrical, and

gas lines, and at other openings.