Installation and Set Up 17

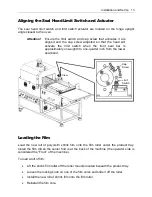

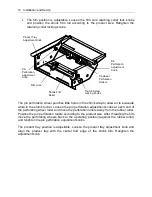

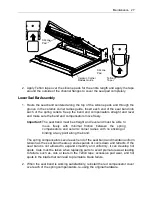

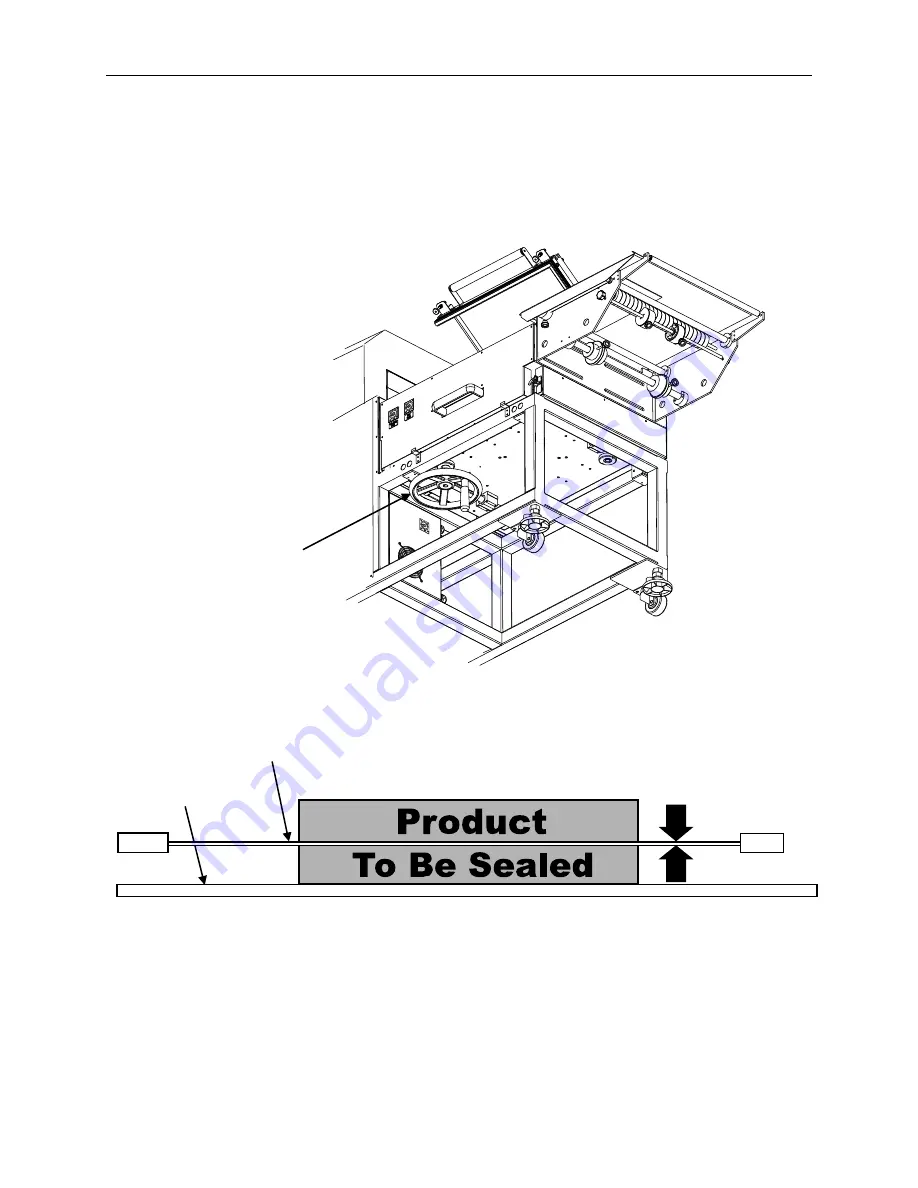

Seal Head Height Adjustment

To adjust the vertical height of the sealing band, use the height adjustment wheel

located under the sealing assembly. Turn the wheel to move the seal band position up

or down.

Position the sealing band as near as possible to the center of the product to be sealed.

Seal Head Height

Adjustment Wheel

Sealing Band

Take Away

Conveyor

Center the sealing

band on the side of the

product to be sealed

Содержание Eastey Value Series

Страница 2: ......

Страница 4: ......

Страница 6: ......

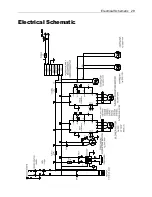

Страница 29: ...Electrical Schematic 29 Electrical Schematic...

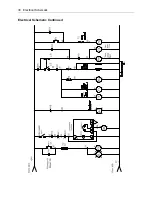

Страница 30: ...30 Electrical Schematic Electrical Schematic Continued...

Страница 31: ...Illustrated Parts List 31 Illustrated Parts List...

Страница 32: ...32 Illustrated Parts List...

Страница 33: ...Illustrated Parts List 33...

Страница 34: ...34 Illustrated Parts List...

Страница 35: ...Illustrated Parts List 35...

Страница 36: ...36 Illustrated Parts List...

Страница 37: ...Illustrated Parts List 37...

Страница 38: ...38 Illustrated Parts List...

Страница 39: ...Illustrated Parts List 39...

Страница 40: ...40 Illustrated Parts List...

Страница 41: ...Illustrated Parts List 41...

Страница 42: ...42 Illustrated Parts List...

Страница 43: ...Illustrated Parts List 43...

Страница 48: ......

Страница 49: ......