Page 10

SOF_7.5.1-07-04

Effective date: 28-Sep-07

MAINTENANCE

User Guide

CustomAir

®

by RAMVAC®

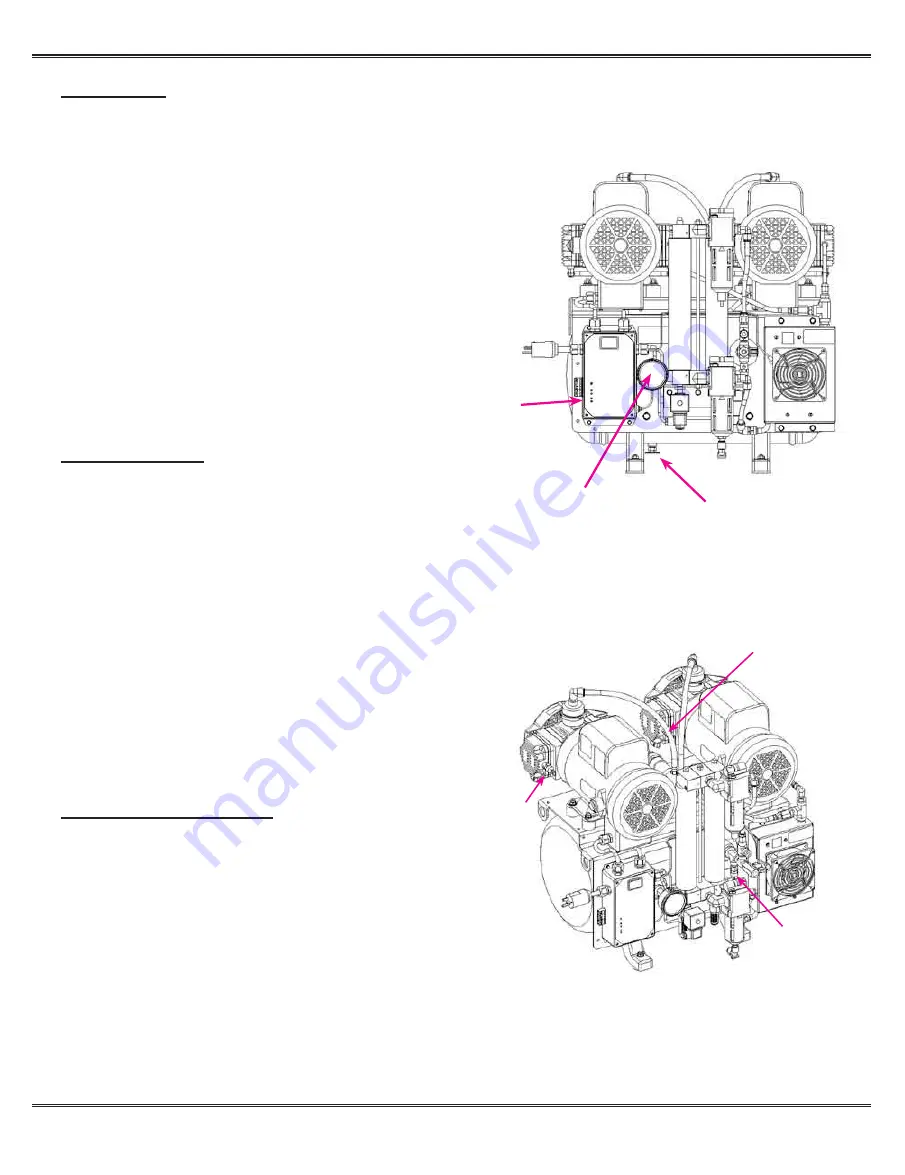

Inspect Dryer

1. Operate the compressor until the pressure of the tank

reaches at least 45 psi.

2. Turn the compressor off with the Power button on

the C1 Control.

3. Carefully open the tank petcock .

4. If no water drains from the tank when the valve is opened the

dryer is working and go to step 6.

5. If water drains from the tank when the valve is opened the

dryer is not working. See “Dryer Service Procedure” on web

at

www.ramvac.com

or contact

RAMVAC

®

at 1-800-572-6822.

6. Return compressor to service.

Test Safety Valves

1. Run compressor until 45 psi shows on the gauge.

2. While the compressor is still running, pull ring on safety valve.

Note: A loud burst of escaping air will be heard when air is

released from the safety valve.

3. If no air comes out of safety valve, the valve is defective and valve

must be replaced immediately.

Caution:

Bleed air from system before servicing.

4. Repeat procedure for each safety valve. (one for each head plus

one at tank inlet)

5. Return compressor to service.

Test Compressor for Leaks

1. Close valve to facility plumbing.

2. Run compressor until it shuts off at 100 psi.

3. Turn compressor off with the power button on the C1 Control.

4. Let compressor set for 5 minutes.

5. If the pressure drop is more than 5 psi in a 5 minute time period,

leaks must be repaired.

6. Repair if needed.

7. Open valve to facility plumbing.

8. Return compressor to service.

Tank Petcock

C1 Control

Pressure Gauge

Safety Valve

Safety Valve

Safety Valve