38

Radijator Inženjering d.o.o, 36000 Kraljevo, Živojina Lazića - Solunca br.6, Srbija

tel. +381 36 399 140, fax. +381 36 399 150, http://www.radijator.rs

Starting the boiler on biomass

Fill the silo with fuel. The silo has the capacity of 240l. It is required to close the silo’s lid.

Make sure that the safety flap of the silo is positioned so that the length of the flap moving

channel is 15-20mm (see picture 15)

If the safety flap is in the lower-end position, all air goes through the fuel mass and does not allow

flames to return. If the flap is in the upper-end position, all air goes to combustion nozzles in the grey

cast iron. The transport channel and the screw might get so hot and the fuel silo might burst in flames.

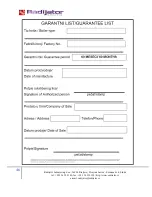

Picture 15. The representation of the position of the safety flap

Inspect if the fan, motor and chainwheel are in their box intact after being transported and put in

the boiler room.

Inspect if the probe for measuring the temperature of exhaust fumes placed inside the smoke pipe.

Without the probe in the pipe, it is impossible for the boiler to operate.

Supply electricity to automatic controls and refill pellets, that is some other fuel up to one-half of

the furnace. That is the height when the fuel inside becomes visible through the lower door of the

boiler. Refilling the furnace can be done in two ways: repeatedly turn the boiler on and off or by

using the special intended function, which is thoroughly explained in section AUTOMATIC

CONTROLS

.

If the boiler’s starting function ON is executed properly, automatic controls will have the electric

combustion heater light on. The electric heater is located in the lower zone of the furnace and if it

is in contact with fuel, after 5 to 6 mins, smoke can be smelled in the furnace.

Then, open the flap due to the possibility of smoke bursting through the lower and upper door.

When the initial flame bursts and the temperature of flue gases exceed 50 °C, the boiler enters the

operating cycle and starts refilling fuel automatically.

After approximately 50 minutes, inspect the temperature of flue gases (explained in section

AUTOMATIC CONTROLS) and if it is relatively high over 180°C, close the boiler’s flap. If the

flap remains open longer, flue gases might exceed 250°C after which the boiler enters the self-

shutdown phase, that is the flame self-maintaining phase.