22

User Instructions

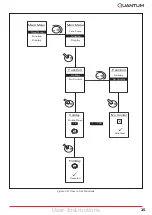

To adjust the time or date, follow the steps below:

- Press the Menu Button

- Select Time/Temp by pressing the control dial

- Rotate the dial to select Set and press the dial to

select

- Press the dial to select Set Date/Time

- Rotate the dial to select the correct day and

press the dial to select

- Rotate the dial to select the correct month and

year and press to select

- Rotate the dial to select the correct time and

press to select

Note: When the cylinder is in normal mode

the date and time is set automatically, this

submenu will state “unavailable when in

comms mode.

11.2.3

Setting the Date and Time

This is accessed from the Home screen and will be

active until the boost temperature is achieved:

- press the advance button to activate

- press the advance button again to de-activate

(see Figure 19)

Note: This can also been done from the

control app.

11.2.5

Activate and De-Activate the

Boost Immersion

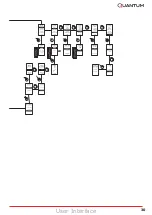

The Quantum cylinder also provides information

about the hot water stored. Information is

provided on the current status of the cylinder as

well as some historical data. This information is

accessed by pressing the selector dial for 3

seconds to display the user information menu;

three choices are available:

1. Temperature – Displays the current, minimum

and maximum temperatures recorded by the

four temperature sensors

11.2.6

Accessing Energy and Tempera-

ture Information

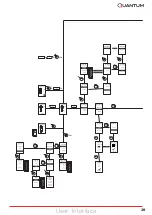

To access and select Holiday Mode or No Control,

follow the steps below:

- Press the menu button

- Rotate the dial to select Timer Mode and press

the dial to select

- Rotate the dial to select one of Holiday or No

Control and press the dial to select

- Set the desired timer conditions and press the

dial to confirm

Holiday mode disables all heating during the

selected holiday period. The holiday period

consists of the remainder of the current day plus

the number of holidays selected in the timer mode

menu.

When in No Control the cylinder heats up to the

primary setpoint temperature when the supply is

active (off peak) or during the selected off peak

tariff window (timed) as selected in the tariff

menu, see section 7.2.1.

11.2.7

Accessing and Setting Functions

Setting the temperature is under the same menu

as the date and time:

- Press the Menu Button

- Select Date/Time/Temp by pressing the control

dial

- Rotate the dial to select Set and press the dial to

select

- Rotate the dial to select Set Temp and press the

dial to select

- Press the dial to select Primary Temp to set the

primary immersion temperature or rotate the

dial to Boost Temp and press the dial to select

the Boost temperature set point

Note: This can also been done from the

control app.

11.2.4

Setting the Primary and Boost

Immersion Heater Temperature

2. Energy

i. Current – Displays current energy

consumption by the immersion heater,

storage capacity is the remaining storage

capacity in the cylinder at that moment of

time and the available hot water volume

relating to the set temperature (stored

now). Should the temperature be higher

than the set temperature, then the mixed

water volume to the set temperature is

stated.

ii. History – gives the energy consump-

tion in kWh available for day -1, week-1,

month-1, and the total energy that the

unit has consumed since it has been in-

stalled.

3. Counter - Displays the total number of hours

logged utilising the boost function.

12 Maintenance

The maintenance of this appliance must

be carried out by suitable qualified person

only. It is recommended to maintain the

unit on an annual basis. Isolate all electrical

supplies from the unit before commencing

work. Danger of electrical shock! See

Section 7.

The Immersion Heater thermostat should

not be removed from the immersion

heater body.

Clean outer cladding of cylinder with a soft

cloth dampened with warm water only. Do

not use abrasive or aggressive cleaning

materials, such as alcohol or petroleum

based solvents, as this may damage the

surface of the product.

!

!

!

Содержание IOT Series

Страница 12: ...12 Installation Figure 9 Wiring Schematic...

Страница 17: ...17 Spare Parts 9 Spare Parts Figure 13 Replacement Part Numbers for Quantum Electric Range of Cylinders...

Страница 31: ...31 Notes...

Страница 32: ...32 Notes...

Страница 33: ...33 Notes...