10

Installation

6.4

Immersion Heaters

The main immersion heater and boost immersion

heater supplied with this cylinder come pre-wired.

A supply cable shall be connected to the unit

through the entry in the electrical enclosure, at

the bottom of the cylinder. Details are given on

how to do this in section 6.5 of this manual. The

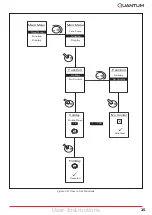

electrical wiring diagram for the product is shown

in Figure 9.

The immersion heater incorporates an

independent non self-resetting over temperature

cut-out. Should the over temperature cut-out

operate, the reset pin will be pushed upwards,

and become level or slightly proud of the cover

at the position marked “Safety”, and the water in

the cylinder will fail to heat. This denotes a fault

somewhere in the system and an appropriate

investigation shall be carried out before the

cut-out is reset. Use a suitable sized implement

to reset the pin by pushing it hard into its original

position.

Should it be necessary to remove the

thermostat from the immersion

element, ensure that the contacts are

re-fitted correctly into the positions on

the element. Failure to do so carries

the risk of overheating the contacts

and thus damaging the appliance.

The immersion heater thermostat must not be

opened under any circumstances.

Figure 4: Correct Operation of Immersion Heater

The cylinder must be filled with

water before switching on the

immersion heater. Failure to do so

will damage the element and void any

guarantee on the product.

6.5.1

Access Connections

To access the electrical connection panel, remove

the enclosure hood by removing the retaining

screws on the sides, as shown in Figure 5. Please

take care when removing the hood, as it is

connected to the cylinder via an earth cable and

a cable to the UI. The water cylinder requires two

supply cables. Where an off-peak supply circuit is

available this can be used and connected to the

‘switched’ supply connections marked on the

terminal block. Where only one wiring circuit is

available two supplies from this circuit are

required. Both supplies must be connected

through a separate double pole isolating switch

which must have a contact separation of at least

3mm in all poles. The cables shall be connected to

the unit through the entry in the electrical

enclosure, at the bottom of the cylinder and

should be connected to the cylinder as shown in

Figure 6.

The cables should be cable-tied securely to the

strain relief provided and if required cable-tied to

the existing cabling on the right-hand side.

The protective tape should be removed from the

contact area between the hood and the cylinder

cladding before commissioning as per Figure 6.

Figure 5: Retaining Screw Positions

6.5

Electrical Connection

The water cylinder has to be connected in

accordance with IEE Wiring Regulations and the

installer carrying out the work has to be suitably

qualified. Before connecting the cylinder, verify

that all the wiring connections on each of the

elements and thermostats have been installed

correctly, that they are secure and that none of

the wires are damaged.

The electrical installation of this cylinder can be

set-up for permanent supply or switched supply

(peak and off-peak). For information on how to

correctly wire either set-up please see Figures 7

or 8 in Section 6.5.2.

Remove protective tape before

commossioning.

The two supply cables must be

fed through the bottom of the

enclosure.

Cable ties [supplied] must be

used to secure the supply

cables into position along the

cable clamp

Figure 6: Supply Cable Anchorage

!

!

Содержание IOT Series

Страница 12: ...12 Installation Figure 9 Wiring Schematic...

Страница 17: ...17 Spare Parts 9 Spare Parts Figure 13 Replacement Part Numbers for Quantum Electric Range of Cylinders...

Страница 31: ...31 Notes...

Страница 32: ...32 Notes...

Страница 33: ...33 Notes...