6

* The system will not perform to its fullest capabilities if volumetric overload is allowed to occur. This

occurs whenever excessive water, above the designed flow rate, is allowed into the system. Excessive

water use or leaking plumbing fixtures may cause this condition.

The AeroCell

®

& Bio-COIR

®

systems are very effective and reliable in the treatment of domestic wastewa-

ter. The problems outlined here occur only in a very small percentage of total installations. They can all

be corrected and most be prevented.

1. Alarm condition exists:

a. Check the breaker for the pump.

b. If the breaker is engaged, set HOA switch to HAND to see if the pump runs.

c. Check the nozzles to be sure they are not clogged and restricting the flow into the module.

d. Check the timer enable float to insure that it is operating properly.

e. Check the timer override float to insure that it is operating properly.

f. Clean the filter panels on the filtered pump vault to assure that effluent is getting into the vault.

g. Check the high water alarm float to see if it is stuck in the up position.

2. Excessive solids in the module:

a. Check to see if the effluent filter cartridge has been removed.

b. Check the septic tank to see if it appears normal. If not, check with the PROPERTY OWNER to

determine what inappropriate materials might have been added to the waste stream.

3. Recirculation device is not splitting properly:

a. Check the out falls for clogging.

b. Check the device for level.

4. Control panel malfunction:

a. Check all fuses and breakers.

b. Check originating power source.

c. Check timer setting to assure it is set according to original design parameters.

5. Effluent quality is out of design parameters:

a. Check the septic tank to see if it needs pumping.

b. Check the dosing tank to see if it needs pumping.

c. Check the out-falls for contamination.

d. Assure that proper procedures were used in taking the sample.

e. Check water usage to insure that it is within design parameters.

f. Check the nozzles for clogging.

g. Check the timer setting to assure it is according to design parameters.

SAFETY

As raw wastewater may and usually does contain some level of unsafe microorganisms, proper respect

and care must be given to safety. When coming into contact with raw sewage, do not fear the contact, but

do take proper precautions to avoid potential danger.

Follow these simple safety precautions whenever exposed to wastewater:

* Always wash with soap and water after handling any contaminated item. The use of good bactericide

Содержание AeroCell ATS-SCAT-8-AC-C500

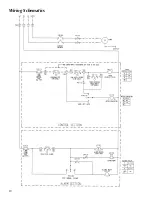

Страница 20: ...19 Wiring Schematics...

Страница 21: ...20 Consecutively Serial Numbered Data Plates Maintenance Sticker...