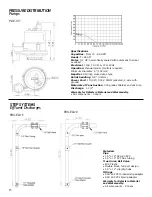

Once sprayed, the effluent moves via gravity down though the media where it is allowed to come

into contact with beneficial microorganisms that serve to treat the effluent to NSF International Stan-

dard 40 Class 1 requirements. After passing through the full depth of media the effluent travels to the

QUANICS

TM

ATS-GRD-100/80/20 recirculation device. The recirculation device splits the flow and dis-

charges 80% back into the treatment stream and 20% to the final disposal point. In periods of low flow,

100% of the treated effluent discharges back into the treatment stream.

INSPECTION SEQUENCE

All onsite wastewater treatment and dispersal systems should be inspected and maintained periodically

in order to provide years of trouble free operation. The AeroCell

®

& Bio-COIR

®

systems require an in-

spection and minimal maintenance every 6 months. Most onsite professionals are familiar with all of the

system components because they are used routinely in other systems. The following inspection sequence

is recommended to determine the current operating condition of the system and what service items must

be completed.

1. Locate all the system components and access openings.

2. Remove all the access lids.

3. Note the water level in the septic tank and its relationship to the top of the effluent filter.

4. Note the water level in the dosing tank and its relationship to the floats.

5. If the timer enable float is up, wait for the control panel to activate on its own time settings. Ensure the

pump run time is as per design parameters. If the timer enable float is down, the pump will need to be

activated manually by switching the HOA switch in the control panel to HAND.

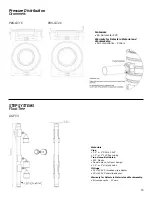

6. While the pump is running, observe the spray nozzles in the treatment module for flow and pressure.

7. While the pump is running, observe the recirculation device for proper flow.

8. Once the current operating condition of the system is established, turn the HOA switch to the OFF posi-

tion in the control panel.

9. Perform service as described in this manual.

SERVICE INSTRUCTIONS

Section 1.0 Septic Tank

The septic tank should be inspected for excessive scum and solids build up. There are several commercial

devices that can be used to measure the sludge layer and determine the pumping frequency of the tank.

Homemade devices can also be used to check the sludge level. No matter what you use to check these

levels, the tank should be pumped when the sludge level in the bottom of the tank reaches within 12

inches of the bottom of the outlet tee of the septic tank.

PROPERTY OWNERs should be encouraged not to use excessive amounts of cleaners and bleach, which

upset the digestive process in the tank. However, normal amounts of these and other common house-

hold products do not cause problems. Non-biodegradable materials such as greases, garbage disposal

by-products, personal hygiene products, cigarettes, paint, chemicals and diapers should not be disposed

of in the tank.

Section 2.0 Effluent Filter

Inspect the septic tank filter and clean it as needed. The length of the maintenance interval for effluent fil-

ters will vary with each individual PROPERTY OWNER. Once a filter is inspected a few times, you should

be able to predict the length of the service interval. Installation and maintenance instructions are included

3

Содержание AeroCell ATS-SCAT-8-AC-C500

Страница 20: ...19 Wiring Schematics...

Страница 21: ...20 Consecutively Serial Numbered Data Plates Maintenance Sticker...