5

Safety (continued)

GENERAL SAFETY

□

□

□

□

□

□

□

□

□

□

□

Before cleaning, repairing, or inspecting, make certain the

tines and all moving parts have stopped. Disconnect the

spark plug wire and ground against the engine to prevent

unintended starting.

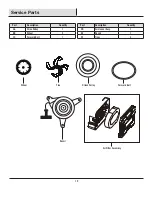

Check the tines and engine mounting bolts at frequent

intervals for proper tightness. Also, visually inspect tines

for damage. Replace with the original equipment

manufacture’s (O.E.M.) parts only, listed in this manual.

“Use of parts which do not meet the original equipment

specifications may lead to improper performance and

compromise safety!”

Keep all nuts, bolts, and screws tight to be sure the

equipment is in safe working condition.

Never tamper with safety devices. Check their proper

operation regularly.

After striking a foreign object, stop the engine, disconnect

the spark plug wire and ground against the engine.

Thoroughly inspect the tiller for any damage.

Repair the damage before starting and operating the tiller.

Tiller components, guards and shields are subject

to wear and damage which could expose moving parts

or allow objects to be thrown. For safety protection,

frequently check components and replace immediately

with original equipment manufacturer’s (O.E.M.) parts only,

listed in this manual. “Use of parts which do not meet the

original equipment specifications may lead to improper

performance and compromise safety!”

Do not change the engine’s governor setting or over-speed

the engine. The governor controls the maximum safe

operating speed of the engine.

Check fuel line, tank, cap, and fittings frequently for cracks

or leaks. Replace if necessary.

Do not crank engine with spark plug removed.

Maintain or replace safety and instruction labels, as

necessary.

Observe proper disposal laws and regulations. Improper

disposal of fluids and materials can harm the environment.

Do not modify engine.

□

To avoid serious injury or death, do not modify engine in any

way. Tampering with the governor setting can lead to a

runaway engine and cause it to operate at unsafe speeds.

Never tamper with factory setting of engine governor.

WARNING:

This machine is equipped with an internal

combustion engine and should not be used on or near any

unimproved forest-covered, brush covered or grass-covered

land unless the engine’s exhaust system is equipped with a

spark arrestor meeting applicable local or state laws (if any).