10

13.01

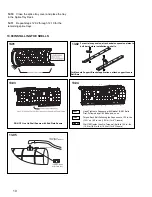

13.00 INSTALLING THE SHELLS

13.02

13.03

For aerial suspension, attach aerial suspension plates to

bolt bars before installation on shells.

For Manhole Support Bracket applications, attach support tees to

Bolt Bars.

13.05

13.04

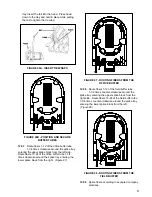

Cap With Air Valve

Install Solid Cap

After Flash Test

Flash Test To

10 PSI (Max) (69 Kpa)

A

B

First

Then

Finally

Hand Tighten in Sequence with Ratchet (All #1 Bolts

First, Followed by all #2 Bolts, and so on...

Torque Each Bolt Following the Sequence to 125 in.-lbs.

(14 N

.

m) (90 in.-lbs. (10 N

.

m) for 4” Closure)

Wait 15 Minutes then Re-Torque all Bolts to 125 in.-lbs.

(14 N

.

m) (90 in.-lbs. (10 N

.

m) for 4” Closure)

DO NOT Line Up Shell Seams with End Plate Seams

1

2

3

4

4

3

2

1

1

2

3

4

4

3

2

1

12.10

Close the splice tray cover and place the tray

in the Splice Tray Rack.

12.11

Repeat steps 12.02 through 12.10 for the

remaining splice trays.