9

PM-1440BV v3 2020-10

Copyright © 2020 Quality Machine Tools, LLC

Section 3 USING THE LATHE

What is not in this section ...

The PM-1440BV is a conventional engine lathe that requires

little explanation except for details specific to this particular

model — speed selection, thread cutting, and the saddle/

cross-slide power feed system. Because the user is assumed

to be familiar with general purpose metal lathes, this section

contains very little tutorial.

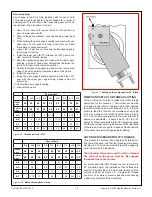

Figure 3-1

Control panel & feed gearbox

(1) Speed range selector; (2) Speed adjust knob; (3) Tachometer

(speed in rpm); (4) Saddle Feed direction selector — shown here in

neutral, no feed; (5) Jog push-button; (6) When set to

0

as shown,

this knob selects feed shaft drive, disengaging the leadscrew; (7)

Emergency E-Stop button — must be OUT for the lathe to function.

Before doing ANYTHING, check the instal-

lation instructions and power-up procedure

in Section 1

STOP the motor before changing speed

RANGE, H to L, L to H

STOP the motor before changing feed DI-

RECTION and saddle feed GEARBOX selec-

tions

Don't use JOG unless the gears are fully

meshed

Before switching power on (switch at back of headstock), be

sure the E-Stop button is not pushed in, (7) Figure 3-1, and

that the Motor Control Lever on the apron is mid-travel, off,

Figure 3-2. Check that the drive train, L or H range, is properly

engaged, then operate the Motor Control Lever to run the spin-

dle in the desired direction. Adjust knob (2) to control spindle

speed.

Figure 3-2

Motor control lever

Mid-travel OFF, Down FORWARD, Up REVERSE

When changing ANY gear selection — speed range, feed direc-

tion, feed speed — first stop the motor. Be patient! It is not always

possible to go directly from one mesh to another, so move the

spindle back and forth by hand while easing the lever/knob into

position. Don’t use JOG to do this! This may damage gears.

SADDLE FEED DIRECTION

The lever below the tachometer determines whether the sad-

dle feed is right to left — the usual direction for turning and

thread cutting — or reversed. The selected direction applies

to both the leadscrew and the saddle/cross slide power feed.

Power feed is OFF when the knob is at 12 o'clock position, as

in the photo.

JOG FEATURE

"Jog" is

momentary-type push-button, active only if the Motor

Control lever is in the mid-travel (OFF) position, Figure 3-2.

Press the button briefly to "nudge" the spindle forward by a

few degrees. Jog can be used to reposition the chuck and/or

workpiece, especially useful when low spindle-speed gearing

makes hand rotation difficult.

The control system can be rewired for "Reverse Jog", see

INITIAL CHECKS, Section 1.