3

PM-1440BV v3 2020-10

Copyright © 2020 Quality Machine Tools, LLC

Section 1 INSTALLATION

THESE ARE THE MAIN POINTS TO WATCH OUT FOR!

But read the following pages for more information

• Handling the lathe is at least a two-man job.

• Lifting gear – sling, hoist or forklift – must be rated for at least 1-1/2 tons.

• Working location of the lathe must allow space for removal of the belt cover at left; also,

access to the coolant system (back of right hand cabinet) and the electrical box at the

back of the headstock.

•

Power requirement is 220V, 60Hz, single phase.

• Extension cord not recommended; if no alternative, use 12 AWG not longer than 20 ft.

• Before connecting power be sure that:

1.

The machine is on a firm footing.

2. Chuck camlocks tight, no wrench left in chuck.

3.

Saddle and cross slide approx. mid-travel, power feed disengaged (Figure 1-8).

4.

The speed control knob is set for a low spindle speed (counter clockwise), with the

headstock gear shift lever set to

L

.

SETTING UP THE LATHE

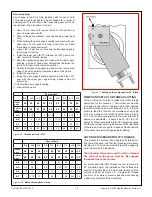

The PM-1440BV is shipped fully assembled in a single pack-

ing case. The machine can be lifted in one piece by an over-

head hoist or forklift with slings and/or chains, all items rated

for a total weight of at least 1-1/2 tons. A suggested setup for

lifting is shown in Figure 1-1.

When selecting a location for the lathe, allow sufficient room at

the right to allow removal/servicing of the leadscrew, feed shaft

and motor control shaft.

Be sure to keep all lifting gear clear of any part of the

lathe, especially the 3 shafts at the front. Use at least 2-by

spreaders.

Figure 1-1

Lifting with slings

Spreader under the bed

keeps slings/chains clear

of feed shafts, etc.

Before lifting, remove the chuck, if installed, then move the

tailstock and saddle as far to the right as possible to balance

the machine at the point(s) of suspension, Figure 1-1.

Check oil levels in all gearboxes before use

With the lathe in its permanent location, level it using metal

shims under the cabinets, or (preferred), install six 500 lb-rated

leveling mounts in the mounting holes of the two stand cabi-

nets, 4 for the left hand cabinet, 2 for the right. The special

mounts shown in Figure 1-2, available from Precision Mat-

thews, allow leveling adjustment from above. To install this

type of mount, remove the threaded stem from the inverted

cup stamping (yellow), then place the cup under the stand with

holes aligned — no washer between stand and mount. If there

is insufficient headroom in the stand, shorten the threaded

stem, then re-install it through the hole in the stand. Once the

stem has bottomed in the mount, further rotation of the stem

(using a wrench) expands the inner core of the mount, thus

raising its upper surface. Secure with the locknut.

Figure 1-2

Top-adjusting leveling mount (optional)

LEVELING

The following procedure ensures that the lathe bed is in the

same state as it was when the lathe was checked for accuracy

in manufacture — level from end to end along the bed, and

from front to back. In other words, no warping.

Make sure all leveling mounts and/or shims are

properly

weight bearing

, firmly in contact with the floor. Check and ad

-

just level from end to end using a precision machinist’s level, if