20

Copyright © 2020 Quality Machine Tools, LLC

PM-1228VF v3 2020-10

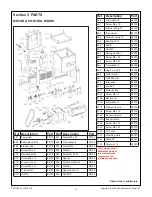

Figure 3-35

General setup for Metric threads

In this setup the lower gear is driven through the

translating gear pair, 86T + 91T.

Upper

gear

30

30

30

35

35

35

50

50

50

60

60

60

Gearbox

A

B

C

A

B

C

A

B

C

A

B

C

1

2

0.75 1.5

1.75

1.25 2.5 0.75 1.5

3

3

0.5

1

2

4

0.5

1

2

1

2

4

5

0.6

0.7

1

2

4

METRIC THREADS

METRIC THREAD CUTTING

Pitch Upper

gear

Gearbox

0.5

30

A4

0.5

35

A3

0.6

30

A5

0.7

35

A5

0.75

30

B2

0.75

60

A2

1.0

30

B4

1.0

35

B3

1.0

50

A5

1.0

60

A4

1.25

50

B2

Pitch Upper

gear

Gearbox

1.5

30

C2

1.5

60

B2

1.75

35

C2

2.0

30

C4

2.0

35

C3

2.0

50

B5

2.0

60

B4

2.50

50

C2

3.0

60

C2

4.0

50

C5

4.0

60

C4

Metric threads sorted by pitch

0.8 mm pitch

For 0.8 mm use the setup for 32 TPI,

Figure 3-33. For practical purposes

the two pitches are interchangeable:

8 mm = 0.31496”, 1/32 = 0.31250”

How a non-metric leadscrew cuts metric threads

This is done by “translating” the leadscrew drive, running it slower than

for US threads by the factor 86T/91T = 0.945. To see how this works,

compare the US setup for 8 TPI (0.125” pitch) with the metric setup

for 3 mm pitch. Both use the same 60T upper gear and the same C2

gearbox setting, but the leadscrew turns more slowly — so 0.125“ be-

comes 0.125 x 0.945 = 0.1181” = 3 mm.

Figure 3-36

Setup for 13, 19 and 26 TPI

This is like the metric setup, but with 56T as the middle gear. On the gearbox select

C & 2 for 13 TPI, B & 2 for 26 TPI. For 19 TPI use the 30T upper gear with C & 2.

How the 13 TPI setup works ...

The usual metric setup, Figure 3-35,

assuming a 60T upper gear, gives an

overall shaft ratio of 60/91 x 86/90 =

0.630. With gear selections C and 2 this

cuts a 3 mm pitch thread.

The 13 TPI setup uses the same 60T

upper gear, but a smaller middle gear

(56T), giving a shaft ratio of 60/91 x 56/90

= 0.4102. This turns the leadscrew slower

by the factor 0.4102/0.630 = 0.6511.

What would have been 3 mm pitch

becomes:

3 x 0.6511 = 1.9533 mm

= 0.0769” pitch = 13 TPI.

SPECIAL CASE: 13TPI