22

PM-1030V v5 2020-10

Copyright © 2020 Quality Machine Tools, LLC

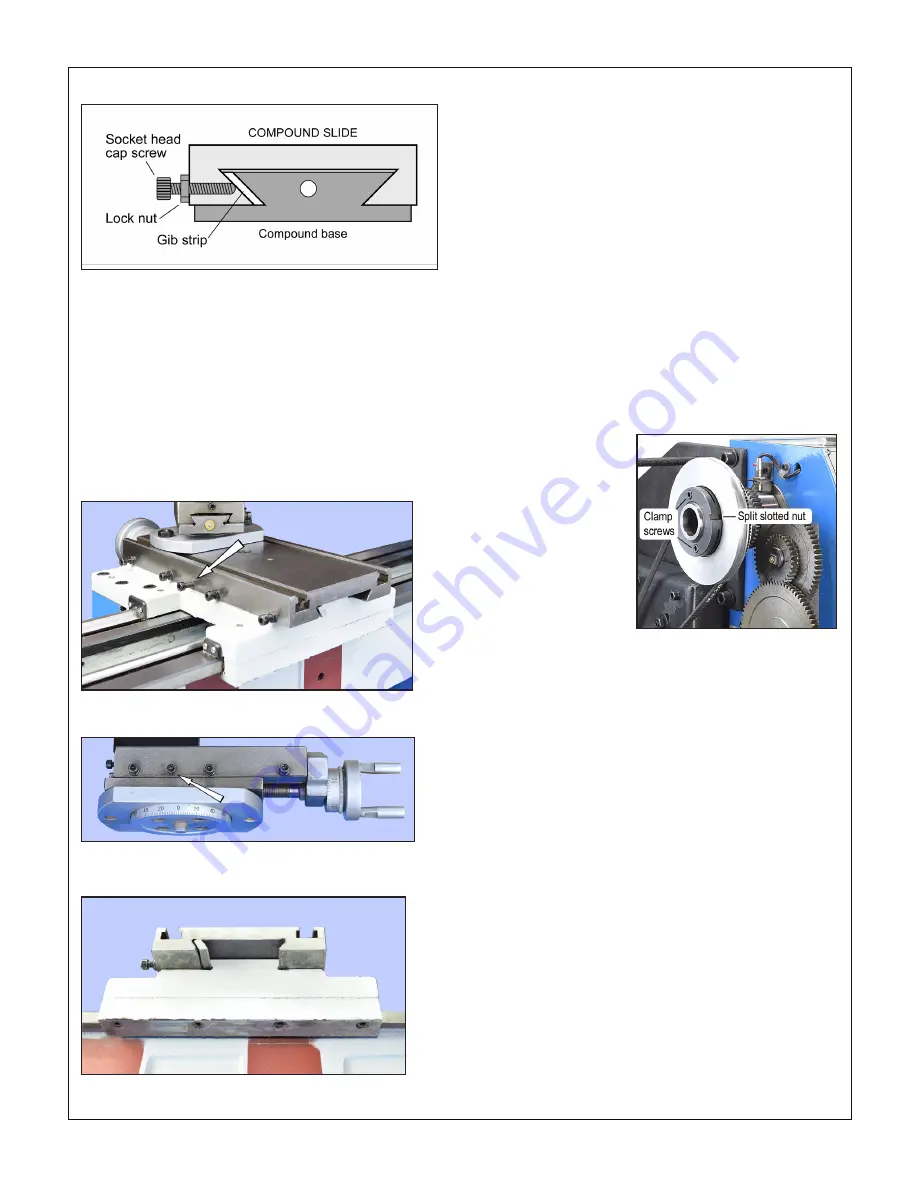

ADJUSTMENT — GIB SCREWS

The cross-slide and compound slide on ground dovetail ways,

Figure 4-8. In the gap between inner and outer dovetails is a

thin strip of cast iron, the

gib strip

. Screws with locknuts on the

sliding component press the gib strip firmly against the inner

dovetail, eliminating unwanted side to side movement while at

the same time allowing smooth positioning by leadscrew and

handwheel. Adjusting the gib screws is a trial and error process

that takes time and patience. Aim for the best compromise of

rigidity and reasonably free slide motion. Too tight means ac-

celerated wear on the ways and leadscrews. Too free means

instability of the cutting tool, inaccuracies and chatter.

Figure 4-8

Gib strip schematic

Figure 4-9

Cross-slide gib screws (four)

Arrowed screw is the lock screw

Figure 4-11

Saddle gib support

The saddle gib is not adjustable

Figure 4-12

Spindle nut

Figure 4-10

Compound gib screws (three)

Arrowed screw is the lock screw

ADJUSTMENT — CROSS-SLIDE BACKLASH

When alternating between clockwise and counter clockwise

rotation, the cross-slide handwheel may move freely a few de-

grees but the cross-slide table stays put.

Cross-slide lost motion is due to two factors: 1. Too-loose at-

tachment of the handwheel attached to the leadscrew, and;

2. Wear in the leadscrew nut, item #32 in the parts diagram,

page 30. This is a split nut that is adjustable by M4 screws,

item #39.

ADJUSTMENT — SPINDLE BEARINGS

The spindle runs on two grease-packed tapered roller bear-

ings. They are factory adjusted, and should need no attention.

If end play becomes evident (workpiece chatter, poor finish,

etc.), this can be corrected by tightening the slotted nut se-

curing the Vee pulley, Figure 4-12. To do this, loosen the two

clamp screws, then gently tighten the slotted nut using a soft

metal drift and hammer. Don't overdo this! Over-tightening can

damage the bearings. Re-tighten the clamp screws.