3

POWER-UP

Upon power-up, all displays and indicators are lit on for approximately 3 seconds. This is followed by the indication of the

indicator model name

on the Upper Readout and the firmware version o n

t h e

L

ower Readout, for

approximately 1 second.

MAIN DISPLAY MODE

After the Power-up display sequence, the Upper Readout starts showing the measured PV (Process Value) and the Lower

Readout displays the user set Units for Process Value. This is the MAIN Display Mode that shall be used most often.

Alarm Status Information

In case of any Alarm (or Alarms) becoming active, the Lower Readout flashes the related Alarm details in the format ‘Ax.YY’,

where x is the Alarm Number (1 or 2) and YY is the Alarm Type (Lo or Hi). For example; if Alarm -1 is active and the set Alarm

Type is Low then the Lower Readout flashes In case of multiple Alarms, each Alarm Status is flashed sequentially with

1 Seconds interval.

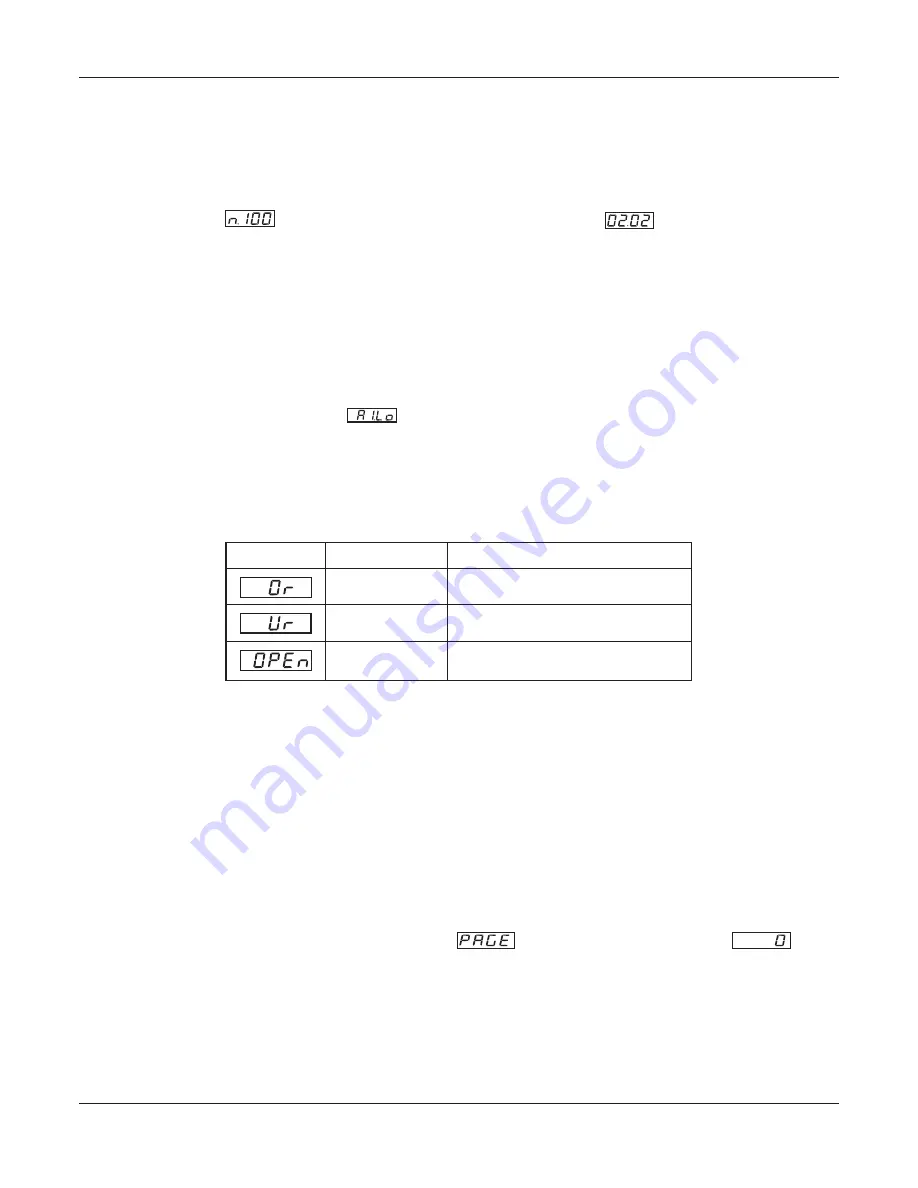

PV Error Indications

The PV Error type is flashed on the Upper Readout. For different errors and the causes, refer Table 2.1 below.

Table 2.1

PV above Max. Range

PV below Min. Range

Message

Error Type

Cause

Thermocouple / RTD broken

Sensor Open

Under-range

Over-range

BASIC OPERATION

ALARM STATUS UNDER PV ERROR CONDITIONS

For Alarm activation, the under-range condition is treated as minimum PV, whereas the over-range and open conditions are

treated as maximum PV. Thus, Process High alarm activates under

Over-range / Open error

. Similarly, Process Low alarm

activates under

Under-range error

.

OPERATOR PAGE AND PARAMETERS

The parameters that require frequent settings are organized on a separate page, called the Operator Page. The availability of

operator parameters is controlled at supervisory level and the parameter setting cannot be locked by the Master Lock.

Accessing Operator Page & Adjusting Parameters

Step through the following sequence to open the operator page and to adjust the operator parameter values.

1. Press and release PAGE key. The Lower Readout shows (PAGE) and Upper Readout shows (0).

2. Press and release ENTER key. The Lower Readout shows prompt for the first available operator parameter and the Upper

Readout shows value for the parameter.

3. Use UP / DOWN keys to adjust the value and then press ENTER key to store the set value and scroll to next parameter.

The

automatically reverts to MAIN Display Mode upon scrolling through the last operator parameter. Alternatively,

indicator

use PAGE key to return to MAIN Display Mode.

User Manual

neuro 100

Section 2