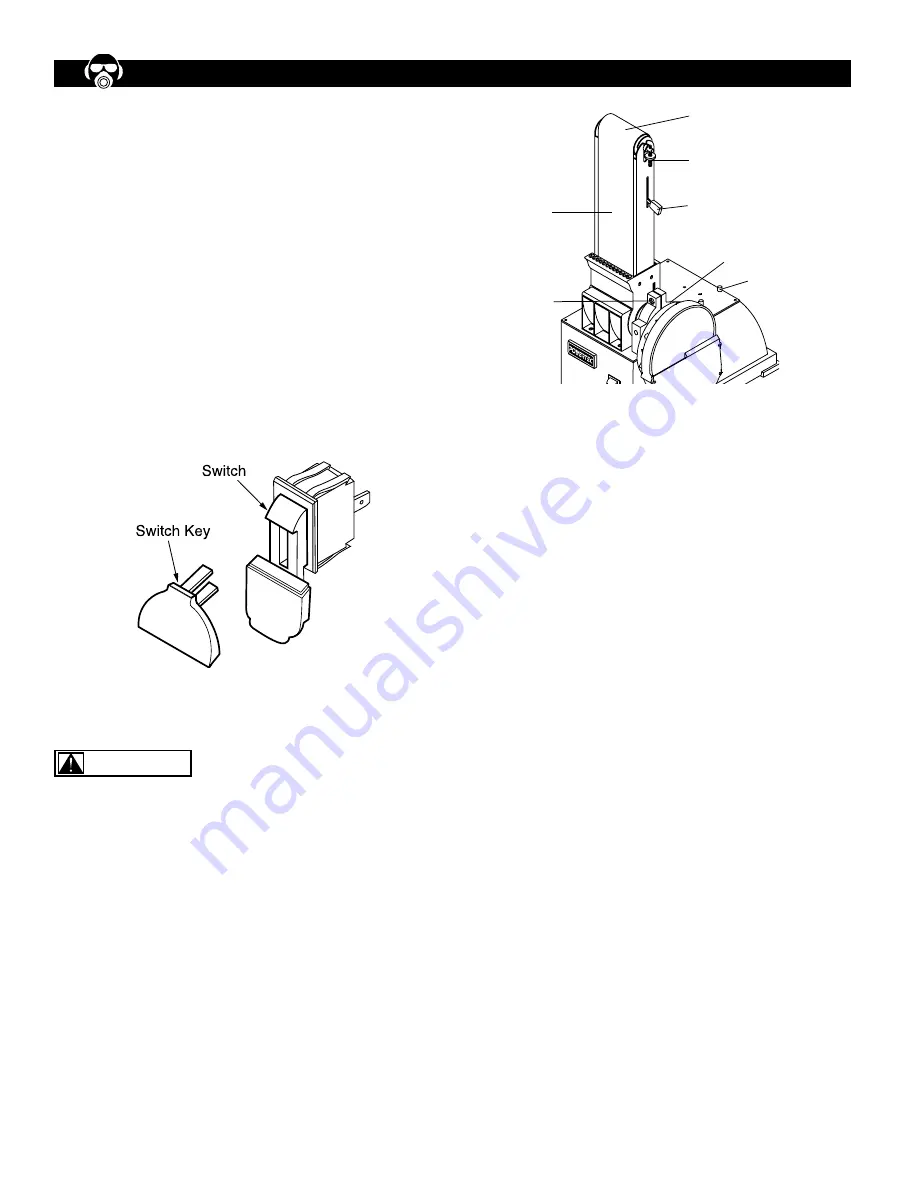

ON/OFF SWITCH

The ON/OFF switch is located in the front of Sander base.

To turn the machine ON, pull the switch to the up position.

To turn the machine OFF, push the switch to the down

position.

NOTE: When the machine is not in use, the machine

should be locked in the “OFF” position to prevent unau-

thorized use.

• To lock the machine, turn the switch to the “OFF”

position and pull the key out. The switch cannot be

turned on without the key.

• If the key is removed when the switch is at the “On”

position, the switch can be turned off but cannot be

turned on again.

• To unlock, place the key into the slot on switch unit until

it snaps.

ADJUST BELT TRACKING MECHANISM

Refer to Figure 9

Keep hands away from sanding belt, idler drum, drive

drum, and any moving parts while conducting Belt

Tracking Mechanism adjustment.

• To check sanding belt level, push the Tension Lever (b)

toward drive drum to tighten the sanding belt.

• To check the belt tracking, switch the machine ON and

OFF quickly. Watch the Sanding Belt (a) movement on

the Idler and Drive Drum. The Sanding Belt should

rotate without moving to the right and left.

• Use the Adjust Tracking Nut (c) to center the Sanding

Belt (a). If the Sanding Belt (a) keeps moving to the

right, turn the Adjust Tracking nut (c) to the left. If the

Sanding Belt (a) keeps moving to the left, turn the Adjust

Tracking nut (c) to the right.

• After each adjustment, switch the machine ON and OFF

quickly and check the Sanding Belt (a) movement again.

Repeat the procedures to adjust the belt tracking until

the Sanding Belt (a) is centered.

ADJUST BELT ASSEMBLY POSITION

Refer to Figure 9

• The Sanding Belt Assembly (d) is designed to function

at any angle between horizontal and vertical position.

There are adjustable positive stops for both horizontal

and vertical positions. The Horizontal Stop is located on

top of the Base (h). It can secure the Sanding Belt

Assembly in horizontal position.

• To change position, use L Wrench to loosen the Socket

Head Bolt (g) in the Pivot Bracket (f). The Pivot Bracket

is located between the Sanding Disc Assembly and The

Sanding belt Assembly.

• Position the Sanding belt Assembly (d) to the desired

angle and tighten the Socket Head Bolt (g) in the Pivot

Bracket (f).

ADJUST TABLE TILT ANGLE

Refer to Figure 10

• The table platform can be adjusted from 0 to 45 degree

(+/- 3°).

• To adjust the table tilt angle, loose the Knob (i) on the

Tilt Angle Scale (k) under the Table Platform (j).

• Tilt the Table Platform (j) to the desired angel as

indicated by the Scale (k). Tighten the Knob (i).

• Check that the distance between the Table Platform (j)

and the sanding surface is 1/16” or less. Do not allow

the sanding surface to touch any part of the Table

Assembly. If adjustment is necessary, loosen the Bolt

(l) that attach the Table Assembly to the Supporting Rod

and adjust the table platform position. Refer to ATTACH

THE TABLE TO USE WITH SANDING BELT section for

details.

Figure 8

Figure 9

OPERATION

6

WARNING

d

g

a

c

b

f

h