LUBRICATION:

You must lubricate the Stapler manually. The

frequency of lubrication is dependent upon

the duty cycle of the Stapler. Continuous duty

requires more frequent oiling than intermittent

duty.

At least every eight (8) hours place two to four

drops of Air Tool Oil into the disconnected air

line male connector attached to the Stapler.

WARNING:

Do not over lubricate the Stapler,

excess oil mist or drops will be vented with

spent air when over lubricated. Excess oil could

stain the wood

fl

ooring, walls or furnishings.

Dry

fi

re the Stapler, without staples, to purge

excess oil, before you begin to staple down

fl

ooring. Before storing the Stapler, lubricate

and cycle the Stapler in insure internal parts are

oil protected from corrosion.

WARNING:

Detergent oil is not recommended

and may damage the seals.

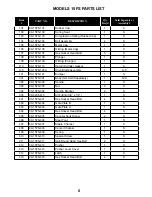

TO LOAD MODEL 15FS:

Pull back the spring loaded pusher lever until it

locks.

Place two sticks (90) PowerStaples into the

Staple Channel Feed slot.

Pull up on the pusher lever to unlock & slowly.

Release it behind the staples.

TO UNLOAD MODEL 15FS:

To remove staples from the channel, pull back

on the staple pusher until it locks. Tilt the

stapler back, the staples will slide back & can

be removed.

PARTS & SERVICE:

When ordering parts include the part number,

part description, PowerStapler model and serial

number.

Be sure to state the quantity of the part(s)

required. Contact your Powerstaple Dealer for

the necessary parts.

WARNING:

Never work on the Stapler if the air

line is attached. Always disconnect the air line

from the Stapler

fi

rst.

4

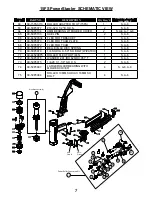

Rack the

fl

ooring into place with the rubber

end of the mallet supplied with the Stapler

Place the Stapler Roller Foot on the tongue-

edge of the

fl

ooring strip to be stapleed. Be

sure the Roller Foot is pressed tightly against

the edge of the

fl

ooring strip above the

tongue.

(Please see page 8 for detailed FLEX

Power Roller operation and adjustment)

Be sure

fl

ooring strips are racked tightly.

Strike the stapler rubber cap with the rubber

capped end of the mallet to discharge the

Stapler.

WARNING:

Never hit the Stapler with

excessive force or with the metal end of the

mallet, this will damage the Stapler.

DO NOT USE THE METAL END OF THE

MALLET TO ACTIVATE THE STAPLER,

use

the rubber capped end only.

Before each use, check all screws to be sure

they are tight. Shock and vibration can loosen

screws. Do not over tighten any screw.

AIR SUPPLY:

The air must be clean and dry. Dirty and/or

wet air will damage the Stapler.

Drywall Dust:

• Using Pneumatic PowerStaplers in

drywall dust conditions will dramatically

decrease the life of the Stapler.

• Drywall dust is abrasive, when cycled

through the Stapler it will cause excessive

wear.

The air source must continuously deliver 80

to 110 psi at 3-1/2 cubic feet of air per minute

to operate the Stapler. For operation, connect

a 1/4” minimum internal diameter and clean

air hose to the Stapler. Be sure the air

regulator is set at 90 psi. If the staple is not

countersunk below the surface of the wood,

turn up the air pressure, but not over 110 psi.

Check for air supply leaks that waste air and

starve the Stapler of air thereby reducing

its performance. There should be no ori

fi

ce

smaller than 1/4” in the air path between the

Regulator and the Stapler.

OPERATING INSTRUCTIONS