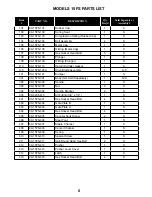

6

Item

#

PART NO.

DESCRIPTION

Qty

Req’d

Sold Separate or

Assembly #

101

09-15FS-101

Rubber Cap

1

S

102

09-15FS-102

Spring Seat

1

S

103

09-15FS-103

Compression Spring (Rubber Cap)

1

S

104

09-15FS-104

Bolt Assembly

4

S

105

09-15FS-105

Metal Cap

1

S

106

09-15FS-106

O-Ring (Metal Cap)

1

S

107

09-15FS-107

Hex Socket Head Bolt

5

S

108

09-15FS-108

Plunger

1

S

109

09-15FS-109

O-Ring (Plunger)

1

S

110

09-15FS-110

Return Cylinder Gasket

1

S

A-5

09-15FS-120A

Drive Blade Assembly

1

A-5

121

09-15FS-121

Bumper

1

S

301

09-15FS-301

Body (Not Sold Separately)

1

N/A

302

09-15FS-302

Handle

1

S

303

09-15FS-303

Nut

4

S

304

09-15FS-304

Handle Bracket

2

S

305

09-445-5418

Air Fitting (3/8” x 1/4” )

1

S

401

09-15FS-401

Hex Socket Head Bolt

4

S

402

09-15FS-402

Gate Plate B

1

S

403

09-15FS-403

Gate Plate A

1

S

404

09-15FS-404

Hex Socket Head Bolt

4

S

405

09-15FS-405

Counter Sunk Screw

2

S

406

09-15FS-406

Steel Foot

1

S

407

09-15FS-407

Staple Channel

1

S

408

09-15FS-408

Center Channel

1

S

409

09-15FS-409

Spring

1

S

410

09-15FS-410

Special Screw

1

S

411

09-15FS-411

Half-Round Head Hex Bolt

2

S

412

09-15FS-412

Pusher

1

S

413

09-15FS-413

Pusher Lever Cover

1

S

414

09-15FS-414

Latch

1

S

418

09-15FS-418

Hex Socket Head Bolt

4

S

MODELS 15FS PARTS LIST