7

Power-Flo Pumps & Systems • 877-24PUMPS • www.powerflopumps.com

Receiving Inspection

Upon receiving the pump, it should be

inspected for damage or shortages.

If damage has occurred, file a claim

immediately with the company that

delivered the pump. If the manual is

removed from the packaging, do not

lose or misplace.

Storage

Any product that is stored for a period

longer than six (6) months from the

date of purchase should be bench

tested prior to installation. A bench

test consists of, checking the impeller

to assure it is free turning and a run

test to assure the motor (and switch

if provided) operate properly. Do not

pump out of liquid.

Controls

Manual models require a separate

approved pump control device or panel

for automatic operation. Be sure the

electrical specification of the control

selected properly match the electrical

specifications of the pump.

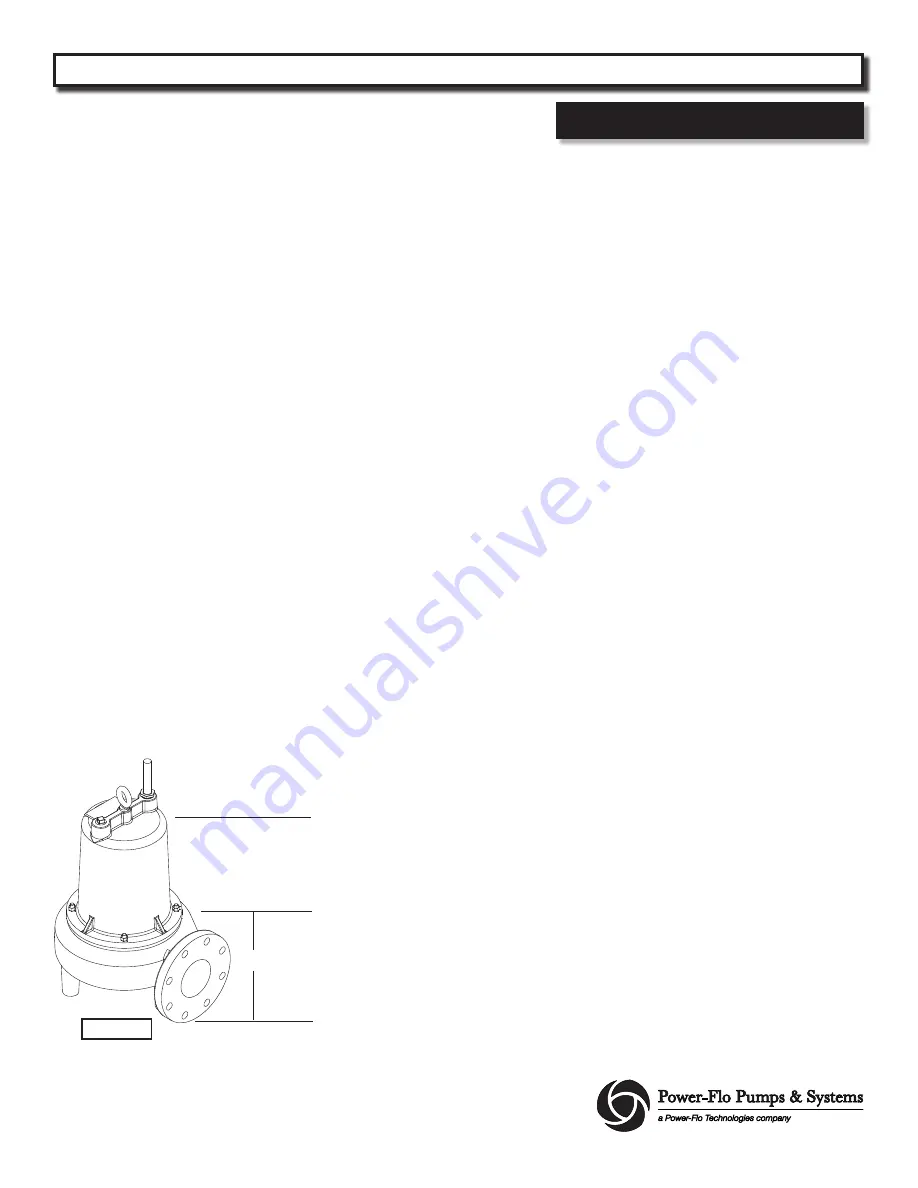

Submergence

The pump should always be operated in

the submerged condition. The minimum

sump liquid level should never be less than

above the pump’s volute (See Figure 1).

Installation

These pumps are recommended for

use in a sump, basin or lift station.

The sump, basin or lift station shall be

sealed and vented in accordance with

local plumbing codes.

This pump is

designed to pump sewage, effluent

or wastewater, nonexplosive and

noncorrosive liquids and shall NOT

be installed in locations classified as

hazardous in accordance with the

National Electrical Code (NEC) ANSI/

NFPA 70 or Canadian Electric Code

(CEC).

The pump should never be

installed in a trench, ditch, or hole with

a dirt bottom. The legs will sink into

the dirt and the suction will become

plugged.

The installation should be at a sufficient

depth to ensure that all plumbing is

below the frost line. If this is not feasible,

remove the check valve and size the

basin to accommodate the additional

backflow volume.

Pumps are most commonly installed

in simplex or duplex stations or basins

with a slide rail system, which allows

the pump(s) to be installed or removed

without requiring personnel to enter

the station, or resting on the basin floor.

Discharge Piping

Discharge piping should be as short

as possible and sized no smaller than

the pump discharge. Do not reduce

the discharge pipe size below that

which is provided on the pump. Both

a check valve and a shut-off valve are

recommended for each pump. The

check valve is used to prevent backflow

into the sump. The shut-off valve is

used to manually stop system flow

during pump servicing.

Liquid Level Controls

The level control(s) should be mounted

on the discharge piping, a cable rack

or float pole. The level control should

have adequate clearance so it cannot

hang up in it’s swing and that the pump

is completely submerged when the

level control is in the “Off” mode. By

adjusting the cord tether the control

level can be changed. One cycle of

operation should be observed, so that any

potential problems can be corrected.

It is recommended that the level control

float should be set to insure that the liquid

in the sump never drops below the top of

the motor housing or a minimum level of

10 inches above the basin floor.

Electrical Connections

Power cable:

The power cable mounted to the pump

must not be modified in any way except

for shortening to a specific application.

Any splice between the pump and the

control panel must be made in

accordance with the electric codes. It is

recommended that a junction box, if used,

be mounted outside the sump or be of

at a minimum Nema 4 construction if

located within the wet well. DO NOT USE

THE POWER CABLE TO LIFT PUMP.

Always rely upon a Certified Electrician

for installation.

Overload Protection:

Single Phase - The stator in-winding

overload protector used is referred to

as an inherent overheating protector

and operates on the combined effect

of temperature and current. This means

that the overload protector will trip out

and shut the pump off if the windings

become too hot, or the load current

passing through them becomes too high.

Figure 1

Receiving & Installation

Recommended

Submergence Level

Minimum

Submergence Level

11”

Bottom of Feet

PF4NC-SS

Non-Clog Pumps

Содержание PF4NC2824SS Series

Страница 6: ...6 Power Flo Pumps Systems 877 24PUMPS www powerflopumps com Performance PF4NC SS Non Clog Pumps...

Страница 21: ...21 Power Flo Pumps Systems 877 24PUMPS www powerflopumps com Notes PF4NC SS Non Clog Pumps...

Страница 22: ...22 Power Flo Pumps Systems 877 24PUMPS www powerflopumps com Notes PF4NC SS Non Clog Pumps...