8655730

6,500 lb Retractable Trailer Jack Quick-Stand Extension

V 4.0

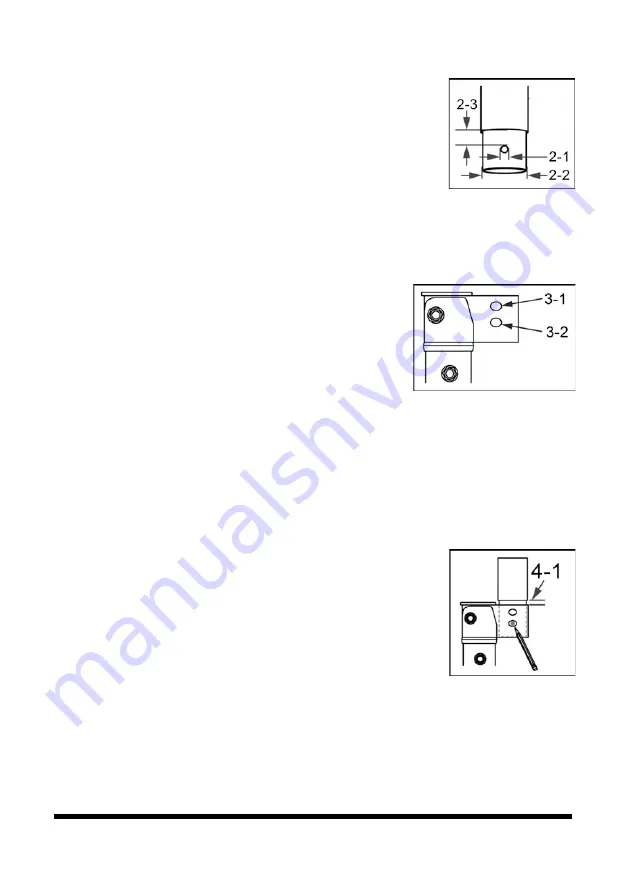

a. Check the bolt hole diameter in the jack’s

extension tube (Fig. 2-1) by inserting one of the

bolts. Drill the hole with a 13/32 in. drill bit to

widen it if the bolt does not fit.

b. You must drill two holes in the extension tube if

the tongue jack has no holes (see Drilling).

6. Measure the diameter of the tongue jack’s extension tube (Fig. 2-2). Use

the reducing sleeve (#5) if the tube diameter is smaller than 2 in. The

reducing sleeve is not needed if the diameter is 2 in. or more.

7. Always use the lower set of holes on the quick-

stand head (Fig. 3-2) with a manual jack. An

electric jack may use the upper or lower holes

depending on the length of the retracted

extension tube.

Measure the distance from the jack cylinder’s

outer tube to the top of the bolt hole on the

extension tube (Fig. 2-3).

a. Use the upper set of holes on the quick-stand, if this distance is less

than 1-1/4 in. (32 mm) (Fig. 3-1).

b. Use the lower set of holes on the quick-stand, if this distance is

greater than 1-1/4 in. (32 mm) (Fig. 3-2).

NOTICE! Using the wrong set of holes can damage an

electric jack, since there must be at least 1/4 in.

clearance (Fig. 4-1) to allow the jack to fully retract

without the outer tube striking the quick-stand head.

8. Slide the quick-stand head over the extension tube of

the tongue jack, aligning the holes in the quick-stand

head with the holes in the extension tube and the

appropriate holes in the reducing sleeve, if used.

a. Slide the reducing sleeve over the extension tube and insert both into the

head of the quick-stand if needed. The holes in the reducing sleeve are

closer to the top end and the sleeve should be installed with the top end up.

Fig. 2

Fig. 3

Fig. 4

6

For technical questions call 1-800-665-8685