010219/0 ControlPro/Diluter

EN - 11

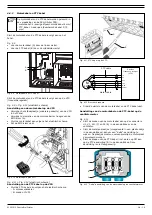

know or determine the airflow in the duct that is necessary to

get the correct throw and air circulation.

The required system pressure must be programmed in the HMI

to keep the airflow at a constant level, independently from the

(increasing) pressure drop caused by the filter cartridges. This

system pressure is called the ‘PID setpoint’, which arranges

the necessary fan speed (Hz) accordingly.

The table below indicates the throw related to the airflow and

fan speed

13

.

Throw

Airflow/

nozzle

Total airflow Frequency

20 m (65 ft)

1000 m�/h

(590 CFM)

6000 m�/h

(3530 CFM)

30 Hz

40 m (130 ft)

1500 m�/h

(885 CFM)

9000 m�/h

(5300 CFM)

50 Hz

For more detailed information, refer to Fig. V on page 37.

Fig. VI shows the horizontal throw per nozzle.

5.3.1 PID setpoint of the fan pressure

To determine and set the PID setpoint, do the following.

• Go to the Settings menu on the HMI.

• Enter PIN.

• Select menu

PID setpoint of the fan pressure

(or enter

2.2.1

on the numeric keypad).

• Select the button

Start fan

.

•

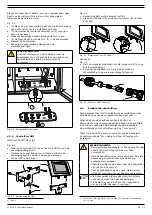

Measure the actual airflow with a flowmeter. Best

measuring position: approx. 500 mm (20 in.) below the

outlet unit of the SCS-Diluter.

• Use the buttons

+

or

─

to determine the setpoint to reach

the desired airflow. At this setpoint, the frequency must

not exceed 45Hz.

• Select

Stop fan

when the desired airflow is reached.

• Select

Finish

to exit the screen. The new values will be

saved.

Fig. 5.1 PID setpoint

6

USE

6.1

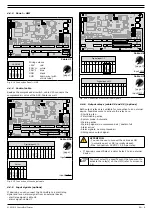

Control panel / Panel

The control panel contains the following controls and

indicators:

13. All nozzles 100% open

Outside

Fig. 6.1 (also refer to Fig. II on page 36)

A White LED | POWER ON

- LED

off: system is off

- LED blinking: system is starting up

- LED on: system is ready

B Green LED | FAN RUNNING

-

LED off: fan is off

- LED blinking: fan is ramping down

14

- LED on: fan is running

C Yellow LED | WARNING

-

LED off: no problem

- LED on

15

: refer to the HMI for the cause of the warning

D Red LED | ALARM

-

LED off: no problem

- LED on

16

: refer to the HMI for the cause of the alarm

E Buzzer | acoustic signal

- together with the ALARM signal (D)

- in some cases: together with the WARNING signal (C)

F Main switch

Inside

ATTENTION

The buttons inside the Panel are for service

purposes only. You can control the entire system via

the HMI, therefore, the buttons inside the Panel are

not necessary for daily use.

G Button | START/STOP FAN

H Button | FILTER CLEANING

-

to activate an additional filter cleaning cycle

- to suppress the buzzer (push and hold for 5 seconds)

I Switch 0-1 | SERVICE MODE

- 0: normal mode

- I: to lock the touch screen of the HMI for service

purposes

Outside

Inside

C

A

B

A B

D

C

E

F

G H

I

C

A

B

A B

D

C

E

F

G H

I

Fig. 6.1 Control panel

6.2

Use

Depending on the specific configuration and system settings

on the HMI, you can activate the fan and cleaning system

manually or have the entire system run fully automatically.

14. Ramp down time: 60 seconds

15. The system continues to run

16. The system stops running

Содержание CONTROLPRO/DILUTER

Страница 40: ...www plymovent com 010219 0 ControlPro Diluter ...