010219/0 ControlPro/Diluter

EN - 10

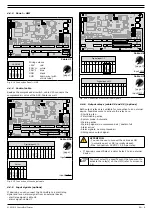

Indicator LED’s

Valves

Dustbin

sensor

Fan Pressure

sensor

Digital input 1-5

RS485 VFD

CAN Slave

CAN HMI

Digital input 6-12

Filter Pressure

sensor

Analog

output

Light tower

Power

Rel

ay

s 1

Rel

ay

s 2

Cable #8

Indicator LED’s

Valves

Dustbin

sensor

Fan Pressure

sensor

Digital input 1-5

RS485 VFD

CAN Slave

CAN HMI

Digital input 6-12

Filter Pressure

sensor

Analog

output

Light tower

Power

Rela

y 1

R

ela

y 2

Ethernet

(for service only)

USB

(firmware updates)

RS-232

(for service only)

Filter pressure

(internal sensor)

Fan pressure

(internal sensor)

+

-

+

-

Valves

1

+ 24V

2

OUT 1

3

GND

4

+ 24V

5

OUT 2

6

GND

Indicator LED’s

1

+ 24V

2

PWR

3

RUN

4

ALA

5

WRN

6

+ 24V

7

BUZ

Dustbin

sensor

1

+ 24V

2

IN 1

3

GND

4

SHD

Fan Pressure

sensor

1

+ 24V

2

IN 2

3

GND

4

SHD

Analog

output

1

OUT

2

GND

3

SHD

Digital input 1-5

1

+ 24V

2

IN 1

3

+ 24V

4

IN 2

5

+ 24V

6

IN 3

7

+ 24V

8

IN 4

9

+ 24V

10

IN 5

11

COM1

12

GND

Digital input 6-12

1

+ 24V

2

IN 6

3

+ 24V

4

IN 7

5

+ 24V

6

IN 8

7

+ 24V

8

IN 9

9

+ 24V

10

IN 10

11

+ 24V

12

IN 11

13

+ 24V

14

IN 12

15

COM2

16

GND

CAN Slave

1 2

CAN_H

3

CAN_L

4

GND

5

SHD

+ 24V

Power

+ 24V

2

GND

1

1 2

A

3

B

4

GND

5

SHD

RS485 VFD

8

1

NO 1

2

NC 1

3

COM 1

4

5

NO 2

6

NC 2

7

COM 2

Light tower

1

+ 24V

2

PWR

3

RUN

4

ALA

5

WRN

6

+ 24V

7

BUZ

Filter Pressure

sensor

1

+ 24V

2

IN 3

3

GND

4

SHD

CAN HMI

1 2

CAN_H

3

CAN_L

4

GND

5

SHD

+ 24V

8

Rela

y 1

R

ela

y 2

IN 5 External start/stop signal

IN 6 Fire alarm (ShieldControl)

IN 7 Sliding valve feedback 1

IN 8 Sliding valve feedback 2

IN 9 Fan alarm

IN 10 Compressed air switch

IN 11 External alert

IN 12 Dustbin level switch

SCS

:

cleaning v

alv

es (1 or 2)

MDB

: (only f

or ShieldC

on

tr

ol)

- out1

sliding v

alv

es

- out2

c

onpr

essed air r

elease

IN 1 BTN start/stop fan

IN 2 BTN filter cleaning

IN 3 Service mode switch

IN 4 Spare

Cable #9

Indicator LED’s

Valves

Dustbin

sensor

Fan Pressure

sensor

Digital input 1-5

RS485 VFD

CAN Slave

CAN HMI

Digital input 6-12

Filter Pressure

sensor

Analog

output

Light tower

Power

Rela

y 1

R

ela

y 2

Ethernet

(for service only)

USB

(firmware updates)

RS-232

(for service only)

Filter pressure

(internal sensor)

Fan pressure

(internal sensor)

+

-

+

-

Valves

1

+ 24V

2

OUT 1

3

GND

4

+ 24V

5

OUT 2

6

GND

Indicator LED’s

1

+ 24V

2

PWR

3

RUN

4

ALA

5

WRN

6

+ 24V

7

BUZ

Dustbin

sensor

1

+ 24V

2

IN 1

3

GND

4

SHD

Fan Pressure

sensor

1

+ 24V

2

IN 2

3

GND

4

SHD

Analog

output

1

OUT

2

GND

3

SHD

Digital input 1-5

1

+ 24V

2

IN 1

3

+ 24V

4

IN 2

5

+ 24V

6

IN 3

7

+ 24V

8

IN 4

9

+ 24V

10

IN 5

11

COM1

12

GND

1

+ 24V

2

IN 6

3

+ 24V

4

IN 7

5

+ 24V

6

IN 8

7

+ 24V

8

IN 9

9

+ 24V

10

IN 10

11

+ 24V

12

IN 11

13

+ 24V

14

IN 12

15

COM2

16

GND

CAN Slave

1 2

CAN_H

3

CAN_L

4

GND

5

SHD

+ 24V

Power

+ 24V

2

GND

1

1 2

A

3

B

4

GND

5

SHD

RS485 VFD

8

1

NO 1

2

NC 1

3

COM 1

4

5

NO 2

6

NC 2

7

COM 2

Light tower

1

+ 24V

2

PWR

RUN

4

ALA

5

WRN

6

+ 24V

7

BUZ

Filter Pressure

sensor

1

+ 24V

2

IN 3

3

GND

4

SHD

CAN HMI

1 2

CAN_H

3

CAN_L

4

GND

5

SHD

+ 24V

8

Rela

y 1

R

ela

y 2

IN 5 External start/stop signal

IN 6 Fire alarm (ShieldControl)

IN 7 Sliding valve feedback 1

IN 8 Sliding valve feedback 2

IN 9 Fan alarm

IN 10 Compressed air switch

IN 11 External alert

IN 12 Dustbin level switch

SCS

:

cleaning v

alv

es (1 or 2)

MDB

: (only f

or ShieldC

on

tr

ol)

- out1

sliding v

alv

es

- out2

c

onpr

essed air r

elease

IN 1 BTN start/stop fan

IN 2 BTN filter cleaning

IN 3 Service mode switch

IN 4 Spare

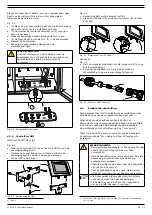

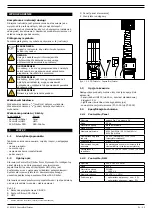

Fig. 4.17 Connection of relay outputs

4.4.7 LightTower (option)

The LightTower contains the same pilot lights as the Panel,

including the buzzer.

Indicator LED’s

Valves

Dustbin

sensor

Fan Pressure

sensor

Digital input 1-5

RS485 VFD

CAN Slave

CAN HMI

Digital input 6-12

Filter Pressure

sensor

Analog

output

Light tower

Power

Rela

ys

Cable #22

Indicator LED’s

Valves

Dustbin

sensor

Fan Pressure

sensor

Digital input 1-5

RS485 VFD

CAN Slave

CAN HMI

Digital input 6-12

Filter Pressure

sensor

Analog

output

Light tower

Power

Rela

y 1

R

ela

y 2

Ethernet

(for service only)

USB

(firmware updates)

RS-232

(for service only)

Filter pressure

(internal sensor)

Fan pressure

(internal sensor)

+

-

+

-

Valves

1

+ 24V

2

OUT 1

3

GND

4

+ 24V

5

OUT 2

6

GND

Indicator LED’s

1

+ 24V

2

PWR

3

RUN

4

ALA

5

WRN

6

+ 24V

7

BUZ

Dustbin

sensor

1

+ 24V

2

IN 1

3

GND

4

SHD

Fan Pressure

sensor

1

+ 24V

2

IN 2

3

GND

4

SHD

Analog

output

1

OUT

2

GND

3

SHD

Digital input 1-5

1

+ 24V

2

IN 1

3

+ 24V

4

IN 2

5

+ 24V

6

IN 3

7

+ 24V

8

IN 4

9

+ 24V

10

IN 5

11

COM1

12

GND

Digital input 6-12

1

+ 24V

2

IN 6

3

+ 24V

4

IN 7

5

+ 24V

6

IN 8

7

+ 24V

8

IN 9

9

+ 24V

10

IN 10

11

+ 24V

12

IN 11

13

+ 24V

14

IN 12

15

COM2

16

GND

CAN Slave

1 2

CAN_H

3

CAN_L

4

GND

5

SHD

+ 24V

Power

+ 24V

2

GND

1

1 2

A

3

B

4

GND

5

SHD

RS485 VFD

8

1

NO 1

2

NC 1

3

COM 1

4

5

NO 2

6

NC 2

7

COM 2

Light tower

1

+ 24V

2

PWR

3

RUN

4

ALA

5

WRN

6

+ 24V

7

BUZ

Filter Pressure

sensor

1

+ 24V

2

IN 3

3

GND

4

SHD

CAN HMI

1 2

CAN_H

3

CAN_L

4

GND

5

SHD

+ 24V

8

Rela

y 1

R

ela

y 2

IN 5 External start/stop signal

IN 6 Fire alarm (ShieldControl)

IN 7 Sliding valve feedback 1

IN 8 Sliding valve feedback 2

IN 9 Fan alarm

IN 10 Compressed air switch

IN 11 External alert

IN 12 Dustbin level switch

SCS

:

cleaning v

alv

es (1 or 2)

MDB

: (only f

or ShieldC

on

tr

ol)

- out1

sliding v

alv

es

- out2

c

onpr

essed air r

elease

IN 1 BTN start/stop fan

IN 2 BTN filter cleaning

IN 3 Service mode switch

IN 4 Spare

Fig. 4.18 Connection of LightTower

4.5

Pneumatic connection

4.5.1 Filter pressure sensor

To monitor the filter pressure, you must connect pneumatic

hoses to the internal filter pressure sensor (+ and –).

• Connect the pneumatic hoses + and – to the corresponding

push-in fittings (A).

•

For connection of the hoses to the SCS-Diluter filter

system, refer to the corresponding manual.

4.5.2 Fan pressure sensor

Refer to the manual of the SCS-Diluter PRO for

installation of the fan pressure sensor to the vertical

duct (ref. paragraph 4.4.11).

To monitor the fan pressure, you must connect the pneumatic

hose to the internal fan pressure sensor.

•

Connect the pneumatic hose to push-in f (B)

11

on

the Panel.

Fig. 4.19

B

Filter –

Fan +

Filter Pressure

+

+

―

Fan Pressure

B

A

Connection of pneumatic hoses to the Panel

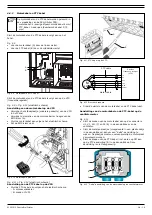

5

COMMISSIONING

5.1

Installation wizard

• Make sure that the Panel is connected to the mains.

• Turn the main switch (refer to Fig. 6.1F) to “

on

”. The

system will start up

12

.

• The HMI starts the installation wizard.

• Complete the installation wizard.

Refer to paragraph 5.3 and 5.3.1 for more

information about the VFD (frequency inverter) and

the PID setpoint.

Select the question mark on the touch

screen for extensive explanation on all

settings.

?

5.2

Extraction fan

• Turn the main switch (refer to Fig. 6.1F) to “

off

” and open

the Panel.

• Turn the bar that is connected to the main switch to

energize the Panel manually.

• Push the START/STOP FAN button (refer to

start the fan.

• Make sure that the direction of rotation of the motor is

correct.

If the direction of rotation of the motor is not correct:

• Invert any two connections (96/97/98) on the VFD to

change the motor direction.

• Push the button again to stop the fan.

5.3

VFD (frequency inverter)

The VFD is integrated in the Panel. The fan speed is controlled

by the system pressure. To operate the system, you must

11.

Push-in fitting – (minus) remains unused

12. Indication: the white LED on the Panel is blinking

Содержание CONTROLPRO/DILUTER

Страница 40: ...www plymovent com 010219 0 ControlPro Diluter ...