Automist Smartscan

®

Handbook v1.2.3

Plumis Ltd Copyright © 2017. All Rights Reserved.

Page 38 of 64

S MA RT SC AN

®

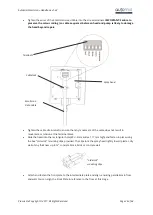

C) Connecting the Water Supply

IMPORTANT:

The flow to a fire suppression device must be ensured when using a domestic water

supply. This can be assumed when there is only a single pump connected because of its very low (6

lpm) flow requirement. However, if more than one pump is being linked to work simultaneously in a

fire, a survey needs to be carried out to ensure that there will be water supply available to both the

Automist pumps and the normal domestic supply in its worst condition. Otherwise a priority valve or

a booster pump may need to be used to provide the required flow and pressure. It is responsibility of

the installer to ensure the water supply to the Automist pumps is adequate.

The water supply should comply as follows:

•

A check valve must be installed to ensure back flow protection to the mains water (supplied in kit).

•

WRAS approved isolation valves (or equivalent) are required so that the Automist Smartscan

system can be shut off from the water main. All such valves should be labelled with the included

warranty void anti-tamper sticker. This enables clear identification of any tampering with the

water valve (note: spare stickers can be ordered from Plumis)

•

Priority valves are not normally required but should be used in circumstances where the water

supply may otherwise be inadequate.

Position the pump unit as closely as possible to the mains water supply pipes.

IMPORTANT:

If new pipe has been fitted, remember to flush out any contaminants before connecting to

Automist Smartscan, to avoid clogging the nozzle.

Connect the high pressure hose from the assembled head to the outlet on the pump. Plumis supplies

suitable high-

pressure hoses. If using another brand of hose, follow Plumis’s guidance note, available on

the Plumis Partner Site. All high pressure hoses should have a minimum working pressure of 150 bar,

minimum internal diameter of 6.3mm and a minimum burst pressure of 600 bar. For hoses longer than 4m,

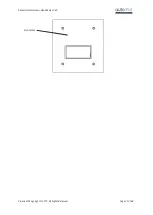

Place sticker over valve body &

handle, ensuring both are

connected by the sticker

When valve is disturbed, the

sticker will disintegrate