10

10.5 Six Monthly Inspections

Service &

Maintenance

10

10.5 Six Monthly Inspections

SERVICE &

MAINTENANCE

For Factory Trained Lift Engineers

As monthly safety checks plus:

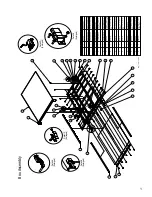

1. Check arm pivot pins, bushes, bearings and retaining grub screws.

2. Check cylinder rod clevis and grub screws.

3. Check cylinders for oil leaks. Replace piston seal if excessive oil leaking from the

cylinder.

4. Remove the bottom sheet, check all hoses and fittings for leaks, wear or perishing.

When bottom sheet is replaced remember to position retaining bolts with nuts (on the

OUTSIDE of stowage box). If access to the lift is not possible COMPLETELY REMOVE

LIFT FROM STOWAGE BOX (ENSURING THE PLATFORM IS CORRECTLY

SUPPORTED)

5. Check guide bearings, cam followers and carriage mechanisms.

6. With the lift fully powered out, and the bottom sheet removed: Clean the interior of the

stowage cassette and degrease the side tracks and guide racks with solvent. DO NOT

GREASE TRACKS OR CENTRE GUIDE, USE SILICONE SPRAY OR ACF50 ONLY.

7. Check the UMBILICAL (main hydro/electrical cable between carriage and inside of box)

for signs of wear, if split or damaged this must be replaced! NOTE: Umbilical should not

be twisted.

8. Check platform wear strips (on underside of platform extension surface) for wear, or

‘fastening protrusion’ replace if necessary.

9. Check bridging plate for correct operation. The bridging plate must land flush with the

vehicle floor and NOT form a trip hazard.

10. Check that the platform does not have a side-to-side ‘kick’. If a ‘kick’ is present the lifting

cylinders should be adjusted.

11. Check that the lift mounting brackets and track bolts are tight / secure and free from

damage. Corrosion in this area of the lift is likely to occur, however if in an advanced

state components should be exchanged for new items.

12. Check manual hand pump operation (see Auxiliary Hand Pump Operation Procedure),

lubricate all pivot points. REMEMBER TO RETURN ANY MANUAL OVERRIDE TAPS

TO THEIR CLOSED POSITION.

13. Check condition and security of arm side guards, replace if damaged.

14. Check right hand arm hose tray, check hose and cable condition and all cable ties are in

place correctly.

15. Check the handset wiring by powering the lift whilst manipulating the cable in any

direction.

IF IN DOUBT CONTACT THE MANUFACTURER

Содержание Access ACC-1150

Страница 7: ...1 1 5 Heath Safety Scooters General ...

Страница 23: ...7 7 7 Floor Height Adjustment Installation 7 INSTALLATION 7 6 Floor Height Adjustment ...

Страница 25: ...7 7 9 Weight Test Installation 7 INSTALLATION 7 8 Weight Test Dynamic Dynamic ...

Страница 30: ...Thread Size Tightening Torque Nm Hydraulic Fitting BSP 1 8 17 0 1 4 34 0 3 8 47 0 ...

Страница 31: ...8 8 1 Standard Operating Procedure Operation 8 OPERATION 8 1 Standard Operating Procedure ...

Страница 32: ...8 8 2 Manual Override Procedure Operation 8 OPERATION 8 2 Manual Override Procedure ...

Страница 35: ...10 10 2 Loler Service Maintenance ...

Страница 44: ...13 13 1 Wiring Diagram Power Pack Diagrams 13 DIAGRAMS 13 1 Wiring Diagram Power Pack ...

Страница 46: ...13 13 3 Hydraulic Diagram Diagrams 13 DIAGRAMS 13 3 Hydraulic Diagram ...

Страница 82: ...15 Notes ...

Страница 83: ...15 Notes ...