21

EN

EN

G

LI

SH

CAREAND MAINTENANCE

WARNING: Always disconnect the electrical cord prior to opening the grill for any inspection, cleaning,

maintenance or servicework. Ensure the grill is completely cooled to avoid injury.

Any Pit Boss®unit will give you many years of flavorful service with minimum cleaning. Follow these cleaning and maintenance

tips to service your grill:

1.

ASH CLEAN-OUT

•

At the bottom of the grill barrel is an ash cleanout feature, giving you easy access

to the inside of your fire box to easily clean it as often as needed. To empty, release

the buckle latch on the ash box hook. While holding the handle, slide the ash box

away from the buckle, then pull down to remove.Onceemptied, replacethe ashbox

by lifting it backinto the bottom of the grill barrel,sliding the ash box towards the

buckle, then fastening the ash box hook with the buckle latch.

WARNING: This feature can only be operated when the grill is cooled down.

2.

HOPPER ASSEMBLY

•

Running all pellets out of your auger system is recommended if your grill will be unused for an extended period

of time. This can be done by simply running your grill, on an empty hopper, until all pellets have emptied from the

auger tube.

•

Checkand clean off any debris from the fan air intake vent, found on the bottom of the hopper. Oncethe hopper

accesspanelis removed (see

Electric Wire Diagram

for diagram), carefully wipe off any greasebuild-up directly on

the fan blades. This ensuresairflow is sufficient to the feed system.

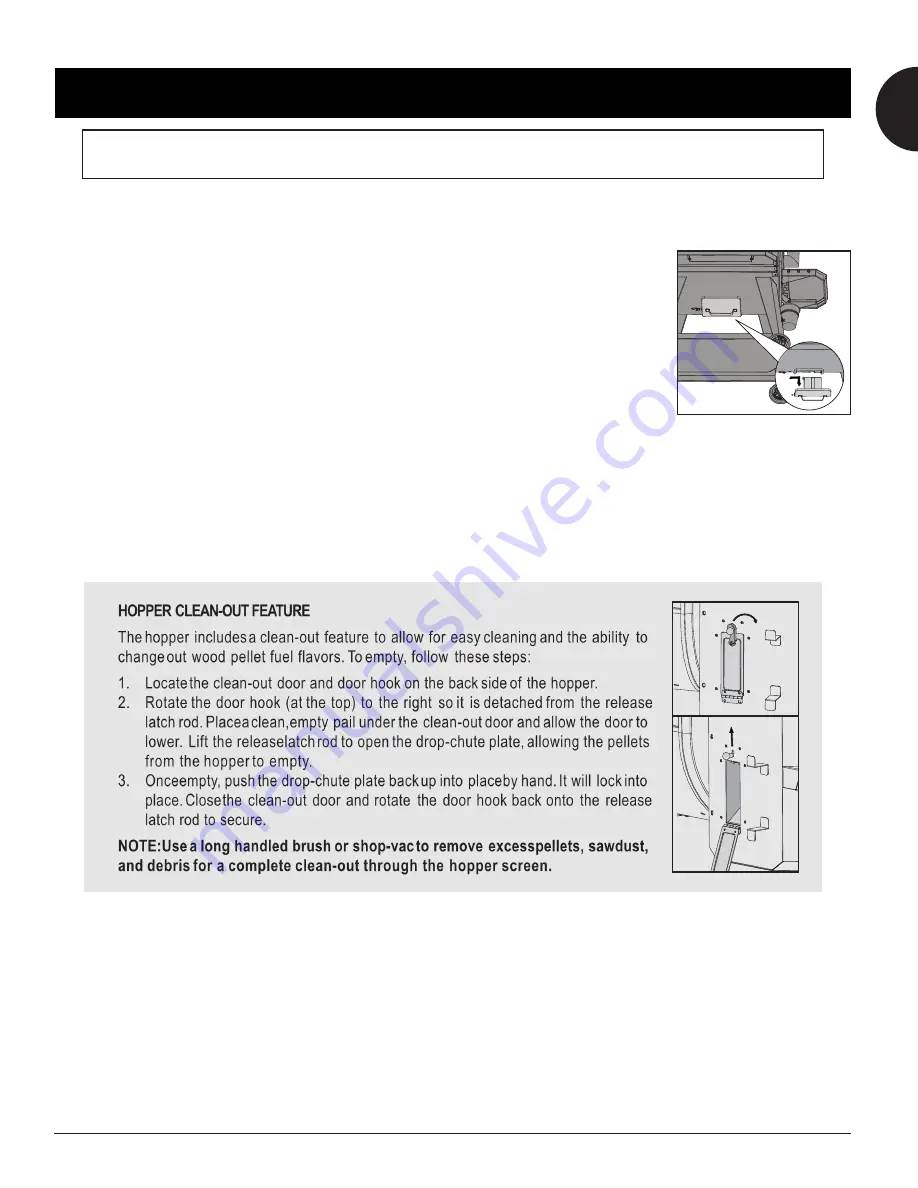

HOPPER CLEAN-OUT FEATURE

The hopper includes a clean-out feature to allow for easy cleaning and the ability to

change out wood pellet fuel flavors. To empty, follow these steps:

1. Locate the clean-out door and door hook on the back side of the hopper.

2. Rotate the door hook (at the top) to the right so it is detached from the release

latch rod. Placea clean,empty pail under the clean-out door and allow the door to

lower. Lift the releaselatch rod to open the drop-chute plate, allowing the pellets

from the hopper to empty.

3. Onceempty, push the drop-chute plate back up into placeby hand. It will lock into

place. Closethe clean-out door and rotate the door hook back onto the release

latch rod to secure.

NOTE:Use a long handled brush or shop-vac to remove excesspellets, sawdust,

and debris for a complete clean-out through the hopper screen.

3.

PROBES

•

Kinks or folds in the probe wires may causedamage. A meat probe not in use should be rolled up in a large, loose coil.

•

Although both the grill probe and the meat probes are stainless steel, do not place in the dishwasher or submerge

in water. Water damage to the internal wires will cause a probe to short-out, causing false readings. If a probe is

damaged, it should be replaced.