D84-P06-01 GB R3

21/04/2021

www.photowatt.com

14

6.2

MOUNTING METHODS FOR FRAMED BIFACIAL

MODULE (CLAMPING)

•

The mechanical load test with these mounting meth-

ods were performed according to IEC 61215.

•

Each module must be securely fastened at a mini-

mum of four points on two opposite sides. The

clamps should be positioned symmetrically. The

clamps should be positioned according to the autho-

rized position ranges defined in table below. Install

and tighten the module clamps to the mounting rails

using the torque stated by the mounting hardware

manufacturer. M8 X 1.25 (5/16”) bolt and nut are used

for this clamping method. The yield strength of bolt

and nut should not be less than 450MPa.

•

Tightening torques should be within 16~20 Nm

(11.8~14.75 ft-lbs) for M8 (5/16”-18 Grade B7) coarse

thread bolts, depending on the bolt class. For the

bolt grade, the technical guideline from the fastener

suppliers should be followed. Different recommen-

dations from specific clamping hardware suppliers

should prevail.

•

The system designer and installer are responsible for

load calculations and for proper design of support

structure.

•

The mounting rails shall be designed to limit as much

as possible shade on module rear side cells.

•

EDF ENR PWT’s warranty may be void in cases where

improper clamps or unsuitable installation methods

are found. When installing inter-modules or end-type

clamps, please take the following measures into ac-

count:

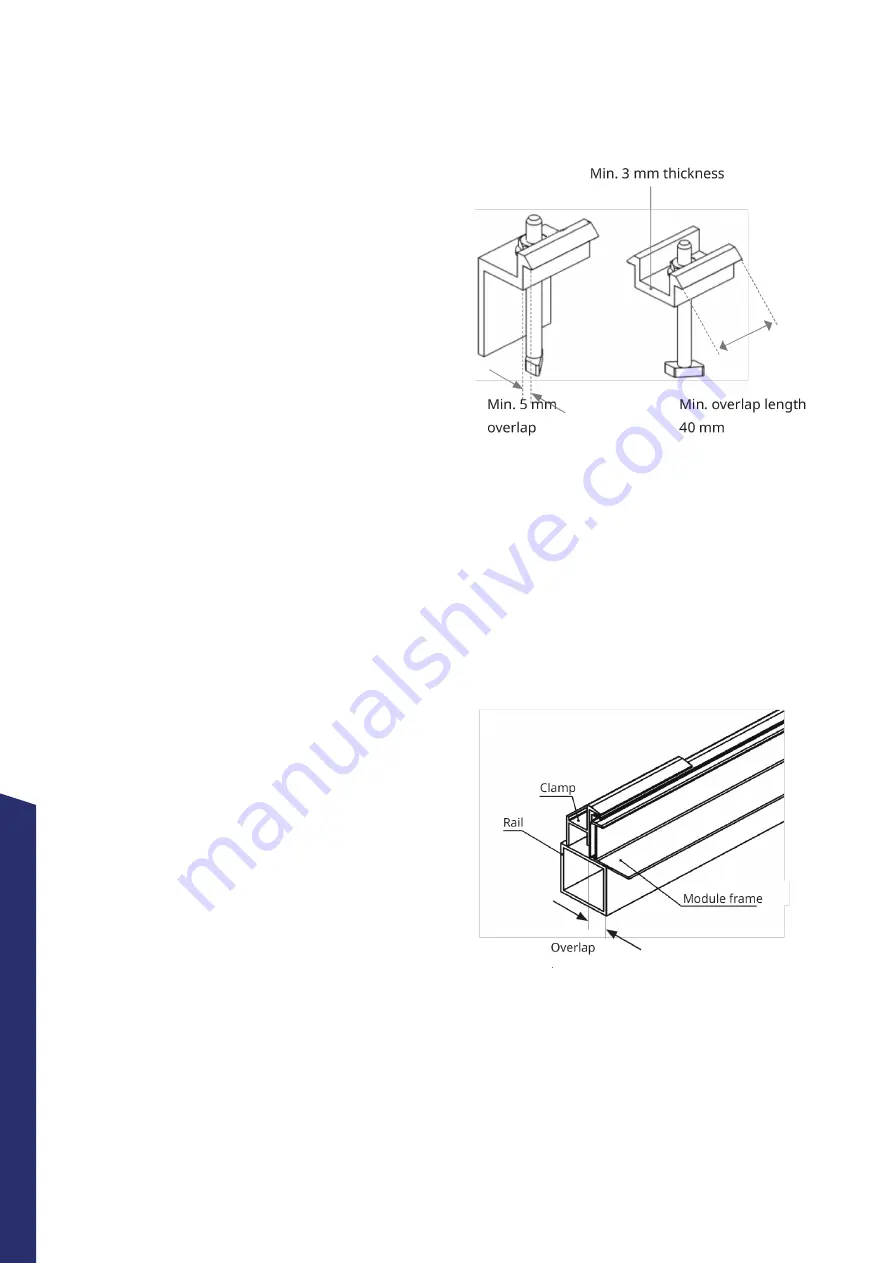

1. Not bend the module frame

2. Not touch or cast shadows on the front glass

3. Not damage the surface of the frame (to the excep-

tion of the clamps with bonding pins)

4. Ensure to overlap the module frame by at least 5 mm

(0.2 in)

5. Overlap in length by at least

a) 80 mm (3.15 in) when 2400 Pa < uplift load ≤ 4000

Pa is required

b) 40 mm (1.57 in) when uplift load ≤ 2400 Pa is re-

quired

6. Ensure the clamp thickness is at least 3 mm (0.12 in)

•

Clamp material should be anodized aluminum alloy

or stainless steel.

•

Clamp positions are of crucial importance for the

reliability of the installation. The clamp centerlines

must only be positioned within the ranges indicated

in table below, depending on the configuration and

load. For configurations where the mounting rails run

parallel to the frame, precautions should be taken to

ensure the bottom flange of the module frame over-

laps the rail by 10 mm (0.4 in).

10 mm