TOOLS AND SUPPLIES NEEDED

• Medium C/A glue

• 30 minute epoxy

• 6 minute epoxy

• Hand or electric drill

• Assorted drill bits

• Modeling knife

• Straight edge ruler

SUGGESTION

To avoid scratching your new airplane, do not unwrap

the pieces until they are needed for assembly. Cover

your workbench with an old towel or brown paper,

both to protect the aircraft and to protect the table.

Keep a couple of jars or bowls handy to hold the

small parts after you open the bag.

NOTE:

1. Please trial fit all the parts. Make sure you have

the correct parts and that they fit and are aligned

properly before gluing! This will assure proper

assembly. The SBACH size 120 is hand made

from natural materials, every plane is unique and

minor adjustments may have to be made.

However, you should find the fit superior and

assembly simple.

2. The painted and plastic parts used in this kit are

fuel proof. However, they are not tolerant of many

harsh chemicals including the following: paint

thinner, C/A glue accelerator, C/A glue debonder

and acetone. Do not let these chemicals come in

contact with the colors on the covering and the

plastic parts.

3. The SBACH size 120 will perform 3-D

aerobatics easily if you use the largest

engines recommended within the engine

range. If you setup your airplane to do 3D

maneuvers, you will need to be throttle

conscious; that is, never apply full throttle on

straight and level flying or in dives to prevent

flutter.

SAFETY PRECAUTION:

• This is not a toy.

• Be sure that no other flyers are using your radio

frequency.

• Do not smoke near fuel.

• Store fuel in a cool, dry place, away from

children and pets.

• Wear safety glasses.

• The glow plug clip must be securely attached to

the glow plug.

• Do not flip the propeller with your fingers.

• Keep loose clothing and wires away from the propeller.

PREPARATIONS

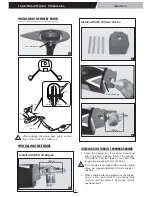

Remove the tape and separate the ailerons

from the wing and the elevators from the stab.

Use a covering iron with a covering sock on

high heat to tighten the covering if necessary.

Apply pressure over sheeted areas to

thoroughly bond the covering to the wood.

• Do not start the engine if people are near. Do not

stand in line with the side of the propeller.

• Make engine adjustments from behind the propeller

only. Do not reach around the spinning propeller.

2

SBACH

Instruction Manual

1

• 2 bender plier

• Wire cutters

• Masking tape

• Thread lock

• Paper towels

• Rubbing alcohol

INSTALLING THE AILERONS

1. Test fit the ailerons to the wing with the hinges.

If the hinges don’t remain centered, stick a pin

through the middle of the hinge to hold it in

position.

TEMPORARY PIN

TO KEEP HINGE

CENTERED

CA glue

2

2. Apply six drops of thin CA to the top and bottom

of each hinge. Do not use CA accelerator. After

the CA has fully hardened, test the hinges by

pulling on the aileron.