RFG-14С Polidek OG p. 6

SAFETY PRECAUTIONS

Safety requirements and measures protecting staff from possible effects of

dangerous factors should be observed during flange spreader operation.

The spreader should be operated with observance of all fire safety requirements.

.

It s forbidden to do the following:

operate the flange spreader at forces exceeding the nominal one stated in the ‘Main

Specifications’ part;

operate the flange spreader with usage of hydraulic liquids of unknown brands and the

liquid purity grade, mix liquid of different brands;

operate the flange spreader in conditions of strong contamination (dust, dirt, sand, etc.)

without additional protective measures for the tool;

relieve pressure in the hydraulic system abruptly that can cause hydraulic shocks; start

operation without having preliminarily removed air from the hydraulic system;

operate the flange spreader if there are leaks in joints, screw joints as well as if the pump,

high-pressure hoses or other elements of the hydraulic system are not operable;

retorque joints or disconnect the high-pressure hose when there is pressure in the

hydraulic system;

bend high-pressure hoses;

act mechanically upon wedge heads under pressure;

operate the flange spreader by uneducated staff members.

PREPARING TOOL TO OPERATION

To prepare the spreader to operation:

Remove it from storage according to requirements of GOST 9.014.

Connect the RFG14 Polidek cylinder to the hydraulic pump through the high-pressure

hose. To do that:

remove gaps from quick connectors;

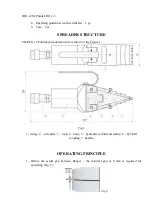

attach the half coupling of the high-pressure hose and the half coupling 6 of the cylinder

5 of RFG 14 Polidek (Fig. 1) and torque the joint with a help of the half coupling acorn

nut against stop fingertight. Do not use any special tools. Connect the hydraulic pump to

the high-pressure hose. Torque joints with a help of a wrench.

Remove air from the hydraulic system assembled this way.

To do that:

open the pressure supply valve of the hydraulic pump;

supplying hydraulic liquid with a help of the pump, spread RFG14 Polidek,

relieve pressure and return RFG14 Polidek to its initial position. Repeat 2-3 times.

Smooth even motion of RFG14 Polidek rods indicates absence of air in the hydraulic

system.