RFG-14M Polidek OG p.7

Use oils stated in the ‘Main Specifications’ part and also other oils with 13.5-16.5 cS

viscosity at temperature of +40

o

C.

If there is a leak of hydraulic liquid in joints of quick connector half couplings, replace

gaskets of quick connectors.

OPERATION PROCEDURE

The operating place should be clean and free from foreign objects.

Only directly involved into the operation staff members can be present in the operating

place. Those members who have not got through the occupational safety and health

instruction and training on spreader operating rules are not admitted to operation.

Mount the spreader on the operating place. To do that:

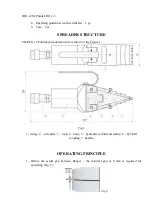

Place the spreader wedge head into the gap between flanges until the vertical side of the

side plates step 2 (Fig.1) of RFG14 Polidek interacts the flange outer surface (Fig. 3).

Spread flanges to desired depth or the maximal spreading value for the given step by

supplying pressure, then place the safety unit into the gap and shift load on it (Fig. 4).

Introduce the wedge head into the gap between flanges and use the next step of wedge

heads for further flange spreading. For maximal flange spreading mount the step block

(Fig. 5). Pressure in the spreader is relieved with a help of the valve on the hand-

operated hydraulic pump.

When the work is finished, disconnect the hose from RFG 14 Polidek, place protective caps on

half couplings of quick connectors, clean the spreader from contaminants; place the wedge head

in the case.

TECHNICAL MAINTENANCE

Technical maintenance is required to keep the spreader operable. To do that, it is required to do

occasionally the following:

1.

Clean the spreader from contaminants.

2.

Check quality of ball joints.

3.

Lubricate spreader dragging surfaces with the Molykote lubricant with molybdenum

disulfide regularly.

4.

In case of long-term intervals in operation of more than 4 months, prepare the tool for

storage in the following order:

- clean the tool from contaminants;

- wipe dry; cover outer surfaces of the tool with storage lubricant.

Store in closed unheated space where air humidity does not exceed 70%.