RFG-14M Polidek OG p. 2

OPERATING GUIDELINES

These operating guidelines merged with a certificate are for the hydraulic flange spreader

of the RFG-14C Polidek series. They contain technical description of the tool, guidelines for

correct and safe operation and specifications.

The manufacturer reserves the right of introducing minor changes and improvement into the

tool design that are not shown in the present operating guidelines.

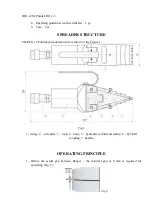

PURPOSE AND SCOPE

The spreader is aimed at flange spreading while replacing gaskets, mounting caps,

replacing taps and valves on heat plants, sanitary and technical systems, oil and gas pipelines,

etc.

The spreader operates at environment temperatures from -30 to +40

o

C.

The designation:

RFG-14M Polidek

, where RFG-14M Polidek stands for hydraulic flange

spreader; 14 – nominal spreading force value, tf.: C – standard set.

MAIN SPECIFICATIONS

1.

Spreading force – 14.5 tf

2.

Minimal gap – 6 mm

3.

First step spacing interval - 15 mm

4.

First step maximal spreading force – 14.5 tf

5.

Spreading width with usage of step blocks – 94 mm*

6.

Operating pressure – 70 MPa

7.

Operating liquid - oils with 13.5-16.5 cS viscosity at temperature of +40o C

8.

Coating of wedge operating parts and side plates (to reduce dragging and prevent from

tearing and corrosion)

9.

RFG14 weight (without step blocks) – 7 kg

10.

⃰-

at Customer’s option spreading width value may be enlarged

LIST OF EQUIPMENT

1.

RFG-14 Wedge head – 2 pc.

2.

Hand-operated hydraulic pump. Operating pressure = 70 MPa – 1 pc.

3.

High-pressure hose – 3 pc.

4.

Safety unit – 2 pc.

5.

Step blocks – 4 pc.

6.

Screw – 4 pc.

7.

Allen wrench – 2 pc.