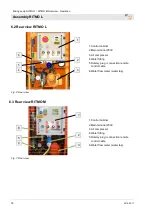

Mixing pump RITMO L / RITMO M Overview - Operation

Intended use control panel

20

2016-02-17

13 Intended use control panel

13.1 Intended purpose control panel

The tool is conceptualised and designed exclusively for the

purpose of use specified here.

Scope of application:

Primary use for water and neutral, non-adhesive

liquids. Also suitable for air and neutral non-

flammable gases.

Maximum operating pressure (inlet pressure) 16

bar.

Outlet pressure infinitely adjustable from 1.5 to 6

bar.

Smallest possible inlet pressure 2.5 bar.

Minimum pressure drop (inlet pressure/outlet

pressure) 1 bar.

Maximum media and ambient temperature 75°C.

Assembly position as desired, preferable vertical.

13.2 Intended purpose solenoid valve

Scope of application:

Solenoid valves for liquid and gaseous media,

aggressive or neutral, can be used different

temperature and pressure ranges

Type 6213 is a 2/2 way solenoid valve with straight

passage, normally closed, with a permanently

coupled membrane system. It operates from 0 bar

and can be used universally for liquids. A minimum

pressure differential of 0.5 bar is required for the

valve to fully open.

13.3 Intended purpose flow meter

Scope of application:

The flow meter is used for the volume

measurement of transparent liquid and gaseous

flows in closed pipelines. Optionally the devices

can be used for flow monitoring.