55

(e)

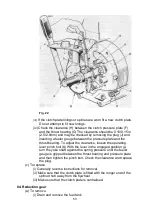

Solenoid

The solenoid should move freely and contact faces be clean and

unburnt Do not attempt to clean the solenoid without disconnecting the

battery

Dynamo and instrument box

(a) Mounting

(i) The dynamo and instrument box must be installed as close to the

engine as possible

(ii) The framework containing the engine and dynamo must be of

sufficiently rigid construction as to prevent any movement

between the engine and dynamo when running This is

particularly important when anti-vibration mountings are used

(iii) IT IS IMPORTANT that the driving and dynamo pulleys are in line

and parallel with each other to within 0.020in (0.50mm). Pulley

alignment may be checked by placing a Straight edge across the

pulley faces The distance between pulley centres to allow for

belt removal and replacement should be 11 in (279mm) A further

11/16 in (17.5mm) is required for tensioning the belt. If further

adjustment is found necessary the belt must be replaced

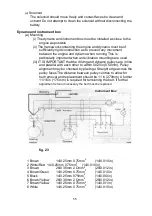

Instrument Box

fig. 23

.

1 Brown

14/0.25mm 0.75mm

2

(14/0.010 in)

2 White/Red 14/0.25mm 0 75mm

3

(14/0.010 in)

3 Brown

28/0 30mm 2 Omm

2

(28/0.012 in)

4 Brown/Green

14/0.25mm 0.75mm

2

(14/0.010 in

5 Black

14/0.25mm 075mm

2

(14/0.0I0 in)

6 Brown/Yellow

28/0 30mm 2 Omm

2

(28/0.012 in)

7 Brown/Yellow

14/0 25mm 0 75mm

2

(14/0.0I1 in)

8 White

14/0.25mm 0 75mm

2

(14/0.010 in)