24

general maintenance

25. To drain cooling system

(a) Remove the plugs from the cylinder This will allow the cooling

water to drain out of the cylinder and cylinder head

(b) Remove the water pump outlet pipe if fitted, and drain the cooling

water from the hose

(c) When replacing the cylinder plugs, it is advisable to wrap 1 ½

turns

of 'P T F E ' tape round the threads This will prevent the plugs

sticking and corroding

There is no need to prime the cooling system when a water pump is

fitted as the pump is self priming.

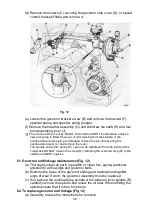

26. To flush out cylinder and cylinder head

(a)

This operation must be carried out every 1000 hours, or every 500

hours with open system cooling, or once a year depending upon which

comes first

(b) Drain and remove the fuel tank.

(c) Drain the cooling water from the cylinder and cylinder head.

(d) Disconnect the cooling water outlet hose and remove the plug and pipe

fittings from the cylinder head

(e) By inserting a piece of wire through the various orifices in the cylinder

and cylinder head. rake out any silt that has collected in the cooling

system This should be carried out while flushing with clean fresh water,

preferably under pressure

(f) The use of a descaling agent wilt be of assistance in removing any

inaccessible or stubborn deposits

(g) It may be found necessary to flush the cooling system frequently when

using water with a high silt content

(h) A new corrosion inhibitor union must be fitted every 1000 hours or once

a year. but the old one may be refitted after 500 hours operation if not

deteriorated and not in operation for more than one year

(i) When replacing the plugs and pipe fittings, it Is advisable to wrap 11/2

turns of "P.T.F.E ' tape round the threads. This will prevent the threads

sticking and corroding.

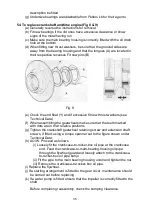

27. To remove water pump (Fig. 5)

(a) Remove the water pipes from the pump.