54

(ii)

Remove the screws securing the bearing housing and remove the

housing complete with the power take-off shah and reduction

gearwheel. Remove the shims

(iii)

Remove the reduction gear housing.

(iv)

Remove the nuts retaining the driving gearwheel.

(b) Reduction gear maintenance

(i) Examine the bearings and fit new parts if rollers or roller tracks

show signs of wear.

(ii) Examine the driving and driven gearwheels. Renew if the teeth

are scored or show signs of wear

(c) To replace

(i) Generally reverse the instructions for removal making sure the oil

seals are in good condition.

(ii) Check the power take-off shaft end float (see Technical Data) and

if not correct, alter the total thickness of the shims behind the

bearing housing.

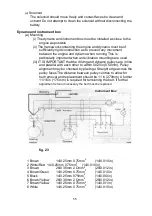

85. Electric starting equipment (negative earth) (Fig. 23)

(a) This consists of a battery-operated starter motor engaging with a gear

ring on the flywheel, a dynamo for battery charging, a regulator and

switch. Operating the switch energises a solenoid which engages a

motor pinion with the gear ring The pinion remains engaged until the

switch is released, but a free-wheel prevents overspeeding the motor

when the engine fires.

Starter motor

(a) Mounting

Make sure the motor is securely mounted on the engine Fit the

mounting bracket to the engine before mounting the starter motor.

(b) Lubrication

Bearings are lubricated on assembly and require no attention between

overhaul periods.

(c) Terminals

Main terminals and all circuit connections must be clean and tight.

Terminal shrouds should be in position

(d) Brush gear

Remove the cover and inspect the brushes and commutator Brushes

should be free in their slides Springs should seat squarely on the

brushes See that the insulation is in good condition The brushes and

commutator should be free from dust and grease and contact surfaces

clean, smooth and uniform in colour