35

description be fitted

(g) Undersize bearings are obtainable from Petters Ltd or their agents.

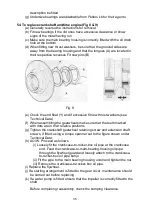

54. To replace crankshaft and time engine (Fig 8 & 9)

(a) Generally reverse the instructions for removal.

(b) Fit new bearings if the old ones have excessive clearance or show

signs of the metal having run

(c) Make sure the main bearing housing is correctly fitted with the oil drain

hole at the bottom

(d) When fitting new thrust washers, be sure that the grooved sides are

away from the bearing housing and that the tongues (A) are located in

their respective recesses Fit new pins (B)

Fig. 8

(e) Check the end float (Y) and if excessive fit new thrust washers (see

Technical Data)

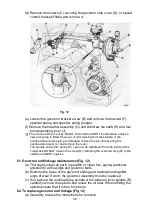

(f) When assembling the gearwheels make sure that the teeth marked

with dots are in their relative positions

(g) Tighten the crankshaft gearwheel retaining screw and extension shaft

screws, if fitted, using a torque spanner set to the figure shown under

Technical Data.

(h) AC1W. Proceed as follows

(i) Loosely fit the crankcase-to-rocker-box oil pipe at the crankcase

end. Feed the crankcase-to-main-bearing-housing oil pipe

through the flywheel guard and loosely attach to the crankcase-

to-rocker-box oil pipe banjo.

(ii) Fit the pipe to the main bearing housing union and tighten the nut.

(iii) Remove the crankcase-to-rocker-box oil pipe.

(i) Replace the flywheel.

(j) If a starting arrangement is fitted to the gear cover, maintenance should

be carried out before replacing

(k) If a water pump is fitted, ensure that the impeller is correctly fitted to the

shaft

Before completing reassembly, check the bumping clearance.