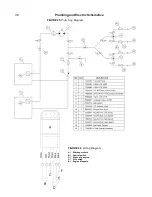

Troubleshooting Manual

30

If

Check

Machine

Machine will not

move with engine

running

Brakes Locked

Drive Belt worn or damaged

Idler Tensioning Spring broken or missing

Clutch Oil

Shift Cable and ends

Shift Arm Bolt missing or loose

Pulleys loose -

Tensioning Idler

V-belt Idler

Engine

Transaxle

Front Axle Shaft Key missing

Transaxle damage-

Oil low

(Do not attempt to repair the following)

Axle bent

Shift Fork bent or broken

Other internal damage

Machine creeps or

continues moving

with Throttle

Lever released

Engine Idle speed too high

Throttle Lever, cable damaged or sticking

Auxiliary Throttle Return Spring broken

Honda Throttle Lever too tight

Carburetor linkage stuck

Excessive

Vibration

Drive Belt slipping or tensioned improperly

Loose Engine Bolts

Engine Vibration Dampers Damaged

Motor Plate Cracked

Fasteners loose or missing

Frame or welds cracked

Ground Speed

Incorrect

Too fast:

Engine RPM too high-

Throttle Lever/Cable improperly adjusted

Too Slow:

Engine RPM too low-

Throttle Lever/Cable improperly adjusted

Belt Slipping, worn or damaged

Transaxle in

LOW GEAR

See Transaxle damage in “Machine will not

move with Engine running”

Transaxle Locked

Front Brake locked

Steering Brakes too tight, dirty, or damaged

Axle Bearing low on grease

Internal Transaxle damage-

(Do not attempt to repair)

Brakes

Stop too fast

Brake Cable adjusted too tight

Brake Band and Drum dirty

Something caught in Brake Band and Drum

Rear Wheel Hub low on grease

Stop too slow

Adjust Brake Cable

Brake Band and Drum wet or contaminated

Brake Cable broken

Brake Band or Drum worn or damaged

Pull to one side

Rear Brake opposite the direction of the turn

is tighter

Rear Brake Cables misadjusted

One Brake Band or Drum worn or damaged

Rear Wheel Hub low on grease

Squeal

Brake Cable adjusted too tight

Brake Band or Drum dirty, worn or damaged

Something caught in Brake Band and Drum

Brakes chatter

Brake Cable adjusted too loose

Brake Band or Drum dirty, worn or damaged

Something caught in Brake Band and Drum

Brake Hot

Brake Cable adjusted too tight

Brake Band or Drum dirty or damaged

Steering

Is difficult

Steering Brake Cable adjusted too loose,

damaged or broken.

Brake Band or drum worn, dirty, or damaged.

Sulky Brakes locked or improperly adjusted

Articulating Joint corroded or damaged

Rear Wheel Hub low on grease

Steering Strut is damaged

Is too easy

Steering Brake Cable adjusted too tight

Brake Band or drum dirty or damaged.

Pulls to one side

Front Steering Brake Cable too tight

Rear Brake (on opposite side) dragging or

locked

Rear Wheel Hub low on grease

If you are experiencing a problem that is not on the list

or are having difficulty, contact PermaGreen Tech

Support at 800-346-2001 or [email protected].

Содержание E1E

Страница 4: ...Page left intentionally blank iii...

Страница 8: ...Page left intentionally blank 4...

Страница 24: ...Page left intentionally blank 20...

Страница 36: ...Page left intentionally blank 32...