Sprayer Operation

Method 2

: Make trim-pass and header-pass as in the previous

section. Fill in the center making squared-off descending spiral

passes to the center spraying as needed.

Either method may be used simultaneously with the spreader

features on the machine on the center of the lawn. (

NOTE

: For best

spray results, you may make separate granular and liquid trim-

passes, and/or use a spot sprayer to lightly feather the edge of the

spray along the borders adjacent to drives, sidewalks etc.) Refer to

Spreader Operation for detailed instructions.

Adjusting Nozzles for proper spray pattern

IMPORTANT: Check and adjust the Spray pattern of ALL

Nozzles daily, prior to treating each lawn, and as needed to verify

that the nozzles are properly aligned and spraying properly.

Adjusting the Broadcast Spray pattern

Park on a flat, concrete or asphalt surface.

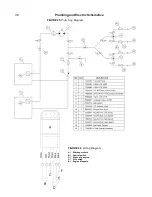

Referring to

FIGURE 15

, select the

HIGH GEAR

Broadcast

Nozzle (

TF-VS 7.5-90

color coded with a green band) by

turning the front Spray Control Valve (

I

) handle to the left. The

rear Spray Selector Valve handle (

J

) must be pointed forward

turning off the

LOW GEAR

nozzles. [If the Half Gallon Nozzle Kit

is installed, both Broadcast Nozzles will be used

simultaneously.]

With the machine in

NEUTRAL

and running, pull the throttle

lever to full operating speed of

3450 RPM

, and pull the Spray

Lever.

Spray for

15 SECONDS

until the spray pattern is visible on the

surface. The spray pattern should resemble the

11-14 FEET

spray pattern in

FIGURE 17

. Adjust as follows:

Rotate the nozzle body on the pipe nipple so that the spray

pattern comes out slightly below parallel with the ground.

Adjust the spray nozzle body so that the pattern width,

measured from outermost droplets to outermost droplets

should be

11 FEET

(3.4 meters) using the

20 PSI

Unloader

Valve or

14 FEET

using the

30 PSI

Unloader Valve.

Increase the pattern width by raising the nozzle level.

Decrease the pattern width by lowering the nozzle level.

Install a bolt from the user-installed Nozzle locating Kit

(enclosed in the parts bag in the Hopper) against the front edge

of the nozzle Cap. If the nozzle body has been moved return it

to the calibrated setting by touching it to the bolt.

Repeat the procedure for the

LOW GEAR

Broadcast Nozzle (

TF

-

VS4-90

color coded with a white band). Remember to turn

off the

HIGH GEAR

Spray Selector Valve. [If the Half Gallon

Nozzle Kit is installed, both Broadcast Nozzles will be used

simultaneously.]

Adjust the trim spray pattern

Park on a flat concrete or asphalt surface.

Referring to

FIGURE 15

, select the

HIGH GEAR

Trim Nozzle

(

DG Tee Jet 9504 EVS

color coded red) by turning the front

Spray Selector Valve handle (

I

) to the right. The rear Spray

Selector Valve handle (

J

) must be pointed forward turning off

the

LOW GEAR

nozzles.

With the machine in neutral and running, pull the throttle lever to

full operating speed of

3450 RPM

, and pull the Spray Lever.

Spray for

15 SECONDS

until the spray pattern is visible on the

surface. The spray pattern should resemble the

3-FOOT

spray

If your calibrated effective spreader width is 8 feet,

install the

30 PSI

unloader cap from the Unloader Valve included in the

8

FOOT

Spray Kit supplied with the machine and adjust the

effective spray pattern to

8 FEET

solid spray and an overall width

of

14 FEET

. trim nozzle provides an even finished distribution over

a spray pattern of

4-FEET

(1.22 meters) on the surface being

treated.

Sprayer Operating Controls

To select which nozzle will spray, point the Spray Control Valve

handle for the gear selected to the desired nozzle either

Broadcast or Trim. The front Spray Selector Valve (

I

) is used for

HIGH GEAR

and the rear Spray selector Valve (

J

) for

LOW

GEAR

. Point Valve Handle left for Broadcast spraying, right

for Trim spraying, and forward to prevent spraying for either

nozzle.

To begin momentary spraying, pull the Spray Lever (

H

)

(

FIGURE 16

) toward the handgrip.

To stop momentary Spraying, release the Spray Lever.

To begin continuous spraying, pull the Spray Lever toward the

handgrip and lock.

To stop continuous spraying, pull and release the Spray Lever

again.

Applying Products with the Sprayer

NOTE: For proper spraying the engine RPM (measured with

the machine in NEUTRAL) MUST be maintained at 3450 RPM,

regardless of whether you are using HIGH or LOW GEAR. If

engine RPM is too low the spray applied will be more than your

Calibrated Rate. If too high, the spray applied will be less than your

Calibrated Rate..

NOTE: For proper spraying, the sprayer calibration must be

verified (refer to Sprayer Calibration in this section).

NOTE: Unless the optional One Half Gallon Spray Kit is used,

Triumph is intended to spray using only one Nozzle at a time.

It is recommended that the products be applied using one of the

following methods for best results.

Method 1

: Make edging pass followed by parallel passes.

Make trim pass around the perimeter of the property and any

ornamental beds spraying as needed.

Select the appropriate gear for the terrain and turf

conditions. Use

LOW GEAR

on hills and in tight areas. Use

HIGH GEAR

on level and open areas.

Select the appropriate Trim Nozzle for the gear selected and

confirm that the other Spray Control Valve is off. Make the

edging pass keeping the edge of the spray pattern inside

the edge of the sidewalk or ornamental bed, spraying as

needed

NOTE

: For best results use a spot sprayer to lightly

feather the edge of the spray along the borders adjacent to

drives, sidewalks etc.

When edging pass is completed stop, make a header pass

overlapping into the first trim pass.

Change gears if desired; and select the appropriate

Broadcast Nozzle for the gear selected and check that the

other Spray Control Valve is off. [If the Half Gallon Nozzle

Kit is installed, both Broadcast Nozzles will be used

simultaneously.]

Fill in the center of the lawn by making parallel passes on

7-

FOOT

or

8-FOOT

centers (corresponding to the Unloader

Valve installed) spraying as needed. At the end of each pass,

enter into the header pass and make a

180 DEGREE

turn.

NOTE

: Avoid re-spraying the areas within the header pass and

trim-pass that were previously sprayed by the effective width

patterns.

26

FIGURE 17

, Broadcast spray pattern

11 to 13 feet

Содержание E1E

Страница 4: ...Page left intentionally blank iii...

Страница 8: ...Page left intentionally blank 4...

Страница 24: ...Page left intentionally blank 20...

Страница 36: ...Page left intentionally blank 32...