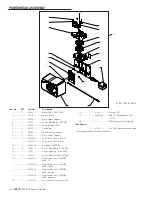

SYSTEM DEFINITIONS

System

Number

System

Description

# of

Tanks/

Controls

Type

Operation Discussion

4

Single Unit

1

Time Clock: No Meter

Immediate: One Meter

Delayed: One Meter

Remote Signal Start: No Meter

Single tank configuration.

5

Interlocked

2, 3, or 4

Immediate: All Meters

Remote Signal Start: No Meter

All tanks in parallel supplying treated water. Each unit in the system

will have its own flow meter/sensor input. The control will delay the

start of Regeneration if another unit is already in Regeneration. Once

that unit has completed a Regeneration cycle, and has returned to

Service,the unit with longest regeneration queue time will begin

Regeneration. No more than one unit will be in Regeneration at a time.

6

Series

Regeneration

2, 3, or 4

Immediate: One Meter

Delayed: One Meter

Remote Signal Start: No Meter

All tanks in parallel supplying treated water. Only #1 control will

monitor flow meter/sensor input. When a regeneration is required

for the system, it will regenerate valve address #1 first, immediately

followed by #2, then #3, then #4 if installed. No more than one unit

will be in Regeneration at a time.

7

Twin

Alternating

2

Immediate: One Meter

Remote Signal Start: No Meter

One tank online supplying treated water, one tank in Standby. Only

#1 control will monitor its flow meter/sensor input. Regeneration of

a unit will begin after the other control has left Standby and returned

to Service. When the Regeneration cycle is complete, the regenerated

unit will enter Standby. Standby on each tank is controlled by the 24

VAC solenoid bypass on the NXT circuit board.

9

Multiple Tank

Alternating

2, 3, or 4

Immediate: All Meters

Remote Signal Start: No Meter

One, two, or three tanks online supplying treated water, one tank in

Standby. Meter/sensor input is required on each tank. Regeneration of

a unit will begin after the other control has left Standby and returned

to Service. When the Regeneration cycle is complete, the regenerated

unit will enter Standby. Standby on each tank is controlled by the 24

VAC solenoid bypass on the NXT circuit board.

TIMER OPERATION

Timer Operation During Programming

The timer enters the Program Mode in Standby or Service

Mode as long as it is not in regeneration. While in the Program

Mode the timer continues to operate normally monitoring

water usage. Timer programming is stored in memory

permanently.

Timer Operation During A Power Failure

All program settings are stored in permanent memory. Current

valve position, cycle step time elapsed, and time of day are all

stored during a power failure. These settings will be restored

upon power re-application. Time is kept during a power failure,

and time of day is adjusted upon power up (as long as power is

restored within 12 hours).

NOTE: The time of day on the main display screen will flash

for 5 minutes when there has been a power outage.

The flashing of the time of day can be stopped by

pressing any button on the display.

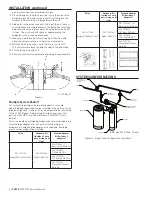

Remote Lockout

The timer does not allow the unit/system to go into

Regeneration until the Regeneration Lockout Input signal to

the unit is cleared. This requires a contact closure to activate

the unit. The recommended gauge wire is 20 with a maximum

length of 500 feet.

Regeneration Day Override Feature

If the Day Override option is turned on and the valve reaches the

set Regeneration Day Override value, the Regeneration Cycle

starts if no other networked unit is in Regeneration. If other

units are in regeneration, it is added to a regeneration queue.

This occurs regardless of the remaining volume available.

WARNING:

Transformer must be grounded and ground

wire must be terminated to the circuit board

grounding screw before installation. Supplied

40VA transformer must be used.

TIMER DISPLAY FEATURES

Shift Button

Adjusts Values to the Left

Up Button

Adjusts Values Up

Volume Remaining

Status LED

Diagnostic Button

View Flow Rate, Peak Flow

Rate, Totalizer, Hours

Between Last Two

Regenerations, Hours Since

Last Regeneration, Adjustable

Volume Remaining, Valve

Position, Send & Receive

Errors, Software Version

Extra Cycle Button

Cycle Valve in

Regeneration/Cycle

Programming Steps

System

Number

Valve

Address

Valve State

(INI, RGQ, SRV, LCK)

Flow

Indicator

Time

of Day

Display Screen

Time of Day alternates

with Error Screen

Example: Valve #, Volume

Remaining, Errors

Down Button

Adjusts Values Down

Figure 5

6 •

FLECK

7000 NXT Service Manual

Содержание Fleck 7000 NXT

Страница 1: ...FLECK 7000 NXT SERVICE MANUAL...

Страница 28: ...DIMENSIONAL DRAWINGS 61500 7000XTR LNE Rev A 28 FLECK 7000 NXT Service Manual...

Страница 29: ...METER FLOW DATA TR18753 Softener TR18688 Filter 41140 02 Rev A 7000NXT VALVE FLECK 7000 NXT Service Manual 29...

Страница 30: ...INJECTOR FLOW DATA TR18755 Rev B 30 FLECK 7000 NXT Service Manual...