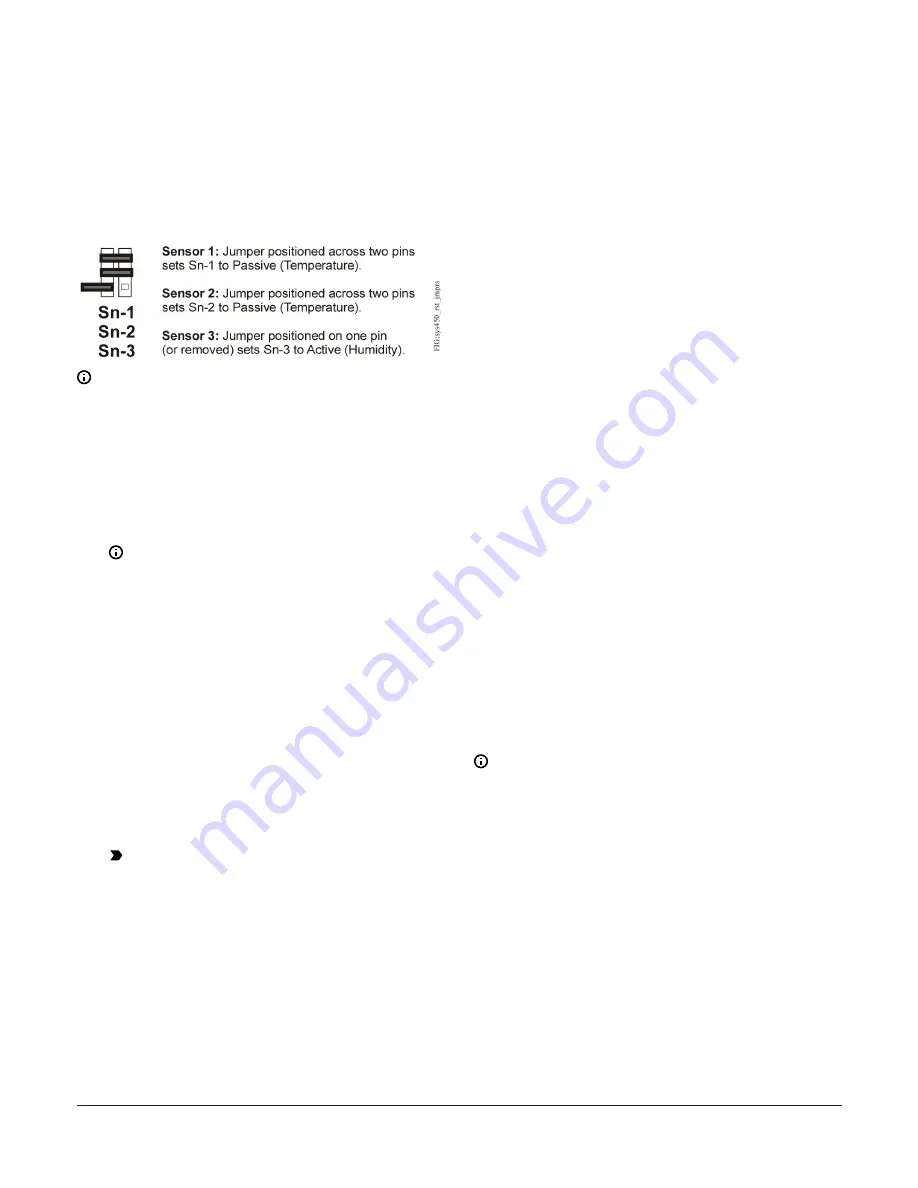

Temperature sensors are passive (2-wire) sensors and the

corresponding jumpers must be positioned across both

pins. Humidity transducers are active (3-wire) sensors and

corresponding jumpers must be positioned on one pin (or

removed completely).

Figure 5 shows the jumper positions for the System 450

Reset Control example shown in Figure 3.

Figure 5: Active/Passive sensor jumper positions for

System 450

Note:

Jumpers are only present in Version 1.

Setting up a control system in the UI

System 450 control modules have a backlit LCD and a

four-button touch pad UI (Figure 4) that enable you to set

up your control system.

1.

Build your control system module assembly and

connect it to power. See

Note:

Every time a module assembly is

powered ON, the control module polls all of

the modules to identify output type (relay

or analog) and assigns a sequential output

number (1 to 9 [0 = 10]) to each output starting

with the control module output on the left. The

output numbers identify each output’s setup

screens in the UI. (See Figure 4.)

2.

Access the System 450 setup screens in the UI. See

Accessing the System 450 Setup screens

3.

Set up the control system sensors (inputs) in the UI.

See

.

4.

Set up the control system outputs in the UI. See

5.

Set up the clock and occupied/unoccupied schedule

in the UI for systems that use setback. See

.

Important:

- When power is disconnected, the time

clock keeps time for 12 hours before

resetting to default; the remaining setup

values entered into the UI remain in non-

volatile memory indefinitely.

- Do not change the module positions

after a System 450 control system is set

up in the UI. System 450 control logic is

set up in the UI according to the Sensor

Types, the output types, and the output

numbers. Changing modules or module

positions in a module assembly that is

already set up in the UI, can change the

output numbers, output types, and the

setup values of the assembly outputs,

which requires setting up the outputs

again.

See Figure 4 for an explanation of the System 450 display

screen and the 4-button touch pad features and functions.

See Table 3 for Reset Control Sensor Types and associated

sensors. See

through

Relay Output and Analog Output that reference the

for System 450 UI setup information and

procedures.

Viewing the Main and System Status

screens

After you install, wire, power on, and set up your control

system in the UI, the Main screens appear on the LCD.

During normal operation, the Main screens automatically

scroll through the current status of each sensor in your

control system, the time and day, and the current Reset

Setpoint value.

The System Status screens display the current status of

each output in your control system and the runtime hours

for each Output Relay. In the Main screen, press

Next

repeatedly to scroll through and view all of the Main and

System Status screens in your control system.

During normal operation, the Reset Control Main screens

automatically scroll through the current temperature or

humidity sensed at each sensor, the current time and day,

and the current calculated Reset Setpoint (RSP) value. See

the Main Screens row in the setup screens flow chart in

.

Note:

• You must set up time and day of week for control

applications that use the setback feature, but you

can also set up time and day on control systems

that do not use the setback feature. If the time

and day have not been set up, the Time/Day

Status screen displays

– –:– –

,

MON

, and

AM

.

• Main screens are view-only; selections cannot be

made in Main screens.

During normal operation while the LCD is auto-scrolling

through the Main screens, press

Next

repeatedly to

scroll through and view the available System Status

screens. Press and hold

Up

and

Down

simultaneously

for 5 seconds to access the Setup Start screens and the

System 450 system setup screens.

In the following figure, the screen examples show Sensor

1 sensing 27°F outdoor air at the Master sensor, Sensor

2 sensing 151°F at the boiler water supply outlet, the

System 450 Series Reset Control Modules with Real-Time Clock and Relay Output Installation Guide

6