Tires can explode due to the following:

1. The wheel rim and tyre are not the same

sizes.

2. The tyre or wheel rim is

damaged.

3. The pressure on tyre

inflation is above max.

pressure recommended by

the manufacturer.

4. The operator fails to comply with the safety

regulations.

Please use the following methods:

1. Remove the valve cover from the valve stem.

2. Check that the air nozzle is completely

depressed over the threads of the valve stem.

3. Check that the tyres and wheel rims are the

same size.

4. Lubricate both the tyre clamp and the wheel

rim, additional lubrication is required if

necessary.

5. Inflate the tyres with pause, when inflating,

check the pressure indicated on the pressure

gauge. Also, check if the clinch is fixed or not.

Repeat the operation above until the clincher is

attached; you need special steps when inflating

a convex rim or double convex rim.

6. Continue to inflate and check the air pressure

frequently until it reaches the desired pressure.

Note! Never exceed the max. pressure

recommended by the tyre manufacturer.

Keep your hands and body away from inflated

tyres.

Only specially trained persons may perform these

operations, do not allow others to use or be near

the tyre changer.

Moving the machine

Use a forklift to move the machine. Disconnect the

tyre changer from the mains and the pneumatic air

supply, lift the base plate and insert the feet of the

forklift trucks. Then mount the tyre changer to a

new position and fix it properly.

Note! The location chosen for fixing the tyre

changer must comply with the safety regulations.

Maintenance

Warning: Only professionals can

Warning: Before performing maintenance,

disconnect the tyre changer from the mains, the

power supply and the pneumatic air supply, and

push the hooks down so that they are open and

close the pedal of the mounting table. Depress

3-4 times to evacuate all compressed air from the

machine. Damaged parts must be replaced by pro

-

fessionals with spare parts provided by the manu

-

do the maintenance. To

extend the life of the

machine, maintain the

machine carefully

according to the operating

instructions. Otherwise, it will

affect the reliability of the machine

or even damage the operator and

others nearby.

facturer.

• Clean the machine once

every day after

usage. Clean the

dirt on the mounting

table with diesel oil once

a week and lubricate the

slides and clamps.

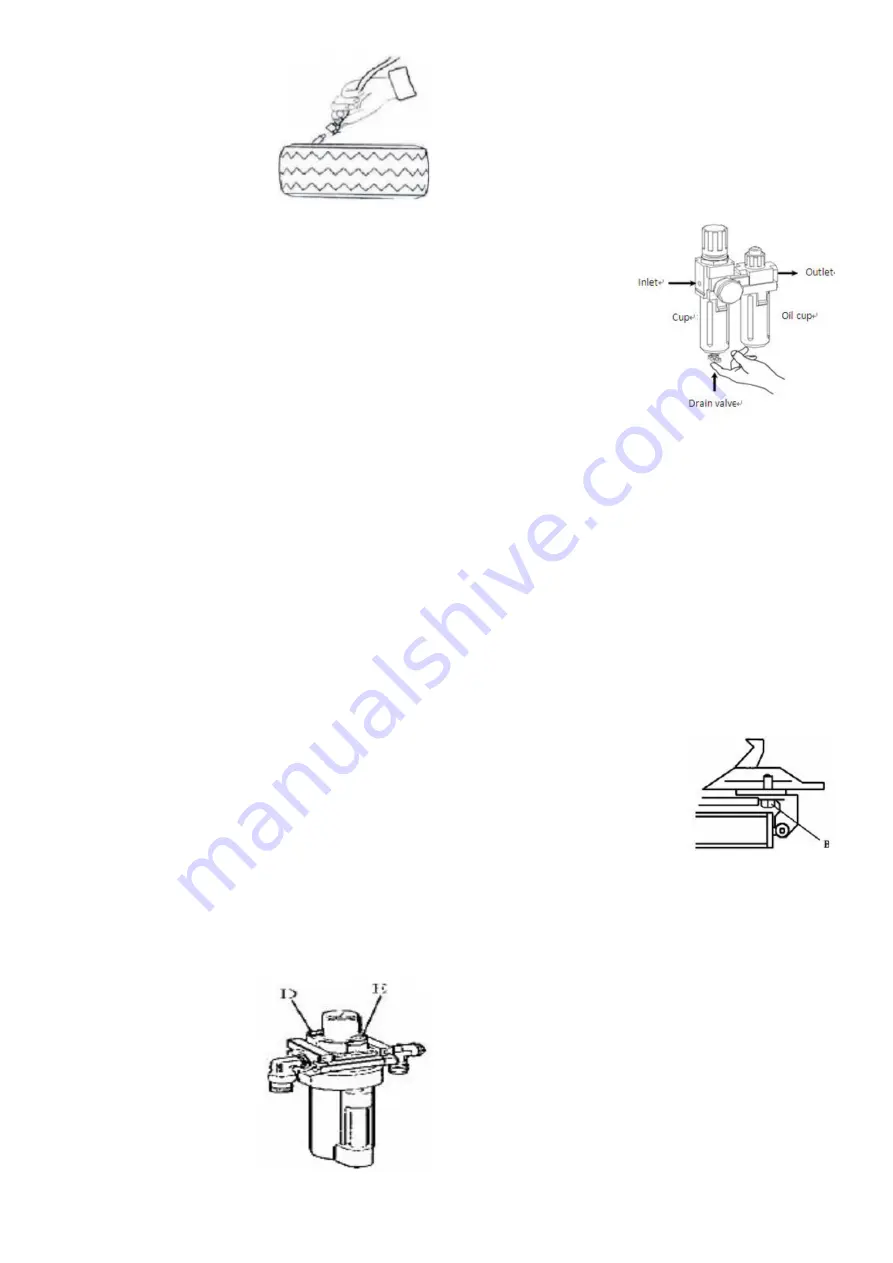

• Subsequent

maintenance must be

done at least once a month: Check the oil level

in the oil feed machine, top up with SAE30 # oil

if necessary. Unscrew with Allen key (E). Based

on the connection of compressed air, firstly,

push up the hooks and step on the pedal to the

assembly table 5-6 times, and check if oil falls

into the oil cup. For continuous operation, press

twice each time, release the oil,

otherwise, adjust the screw (D) that checks that

the oil enters.

• When you have found that there is some

water in the cup, push up the drain valve to

drain water with your fingers. Release your

finger after draining the water, the drain valve

closes automatically.

Note! After the first 20 days, tighten the hooks with

the tightening screws (B) on the

mounting table.

Note! If the mounting table

loses power, check if the belt

is tightened according to the

following steps:

• Remove the left side cover by unscrewing the

screws. Adjust the two screws on the engine

support, keeping a suitable distance between

the engine support and the engine base.

Tighten the belt tension screws.

Warning: Disconnect the machine from the mains

and pneumatic power supply.

Note! If the vertical arm is not locked or does not

meet the 2-3 mm requirement from the bottom of

the mounting / disassembly head to the rim, adjust

the hexagonal locking plate, and adjust (X).

Содержание 514019

Страница 1: ...Tyre changer without a table Däckmaskin utan bord APO 3266 Item No 514019 ...

Страница 10: ......

Страница 19: ......

Страница 20: ......

Страница 21: ......

Страница 22: ......

Страница 23: ......

Страница 24: ......

Страница 25: ......

Страница 26: ......

Страница 27: ......

Страница 28: ......

Страница 29: ......

Страница 30: ......

Страница 31: ......

Страница 32: ...Verktygsboden Erfilux AB Källbäcksrydsgatan 1 SE 507 42 Borås Verktygsboden Borås Sweden 0120504 03 ...