TECHNICAL INSTRUCTIONS

4853989

10/ 2003

Our policy is one of continuous improvement and we reserve the right to alter specifications of our products at any time.

- 18 -

OTHER

Obstruction of liquid passages.

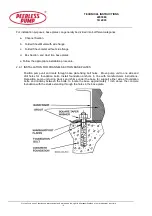

Dismantle pump and inspect passages of impeller and casing. Remove

obstruction.

Defective packing.

Replace packing and sleeves if badly worn.

4.

MAINTENANCE

4.1

ROUTINE MAINTENANCE

This section gives details of routine preventative maintenance. Where repair or major overhaul is required

please contact PEERLESS PUMP COMPANY SERVICE.

4.1.1 GENERAL

Routine maintenance is essential to maintain the plant in a serviceable condition, and a sound

insurance against enforced inopportune shutdown.

A high degree of cleanliness of equipment and surrounding areas should be maintained during all

maintenance procedures.

4.1.2 FREQUENCY OF INSPECTIONS

A general guide is shown in Table 3.

Depending on operation and environmental conditions together with a comparison of previous

inspections, the frequency may be altered to maintain satisfactory operation of the plant to suit

established operating procedures.

4.2

LUBRICATION

GREASE LUBRICATED BEARINGS

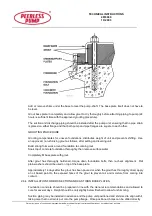

Bearings are initially lubricated during manufacture or re-assembly. The re-greasing interval depends upon

the running speed of the unit:

TABLE 3

BEARING RE-GREASING INTERVALS

PUMP RUNNING SPEED

RE-GREASING INTERVAL

AMOUNT OF GREASE

1450/1750 RPM

5000 HOURS

2 OUNCES

2950/3550 RPM

3000 HOURS

2 OUNCES

To recharge the bearings with fresh grease, use a grease gun through the two lubricating nipples provided.

DO NOT APPLY LUBRICANT WHEN PUMP IS RUNNING.

Every 10,000 hours or 2 years, remove bearings from pump, de-grease, thoroughly clean, recharge with

fresh grease and refit in accordance with re-assembly instruction;

Содержание HYF

Страница 2: ......