TECHNICAL INSTRUCTIONS

4853989

10/ 2003

Our policy is one of continuous improvement and we reserve the right to alter specifications of our products at any time.

- 13 -

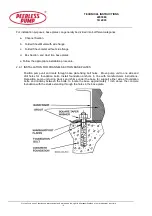

Alignment should be performed after the base plate has been properly set and grout has dried thoroughly

according to instructions. Final alignment should be made by shimming the driver only.

2.8

SUCTION AND DISCHARGE PIPING

The following precautions should be observed during installation:

In the case of channel section and folded metal base plates without side flanges, piping should be run to the

pump. Do not move pump to pipe, this could make final alignment impossible.

Both suction and discharge piping should be supported independently and close to the pump so that no

strain is transmitted to the pump when the flange bolts are tightened. Use pipe hangers or other supports at

intervals necessary to provide support. When expansion joints are used in the piping system, they must be

installed beyond the piping supports closest to the pump.

Install piping as straight as possible, avoiding unnecessary bends. Where necessary, use 45

or

l

ong

sweep 90

f

i

t

t

i

ng

t

o

decr

ease

f

r

i

ct

i

on

l

osses.

Make sure that all piping joints are air tight. Provide pipe expansions when hot fluids are to be pumped.

Where reducers are used, eccentric reducers are to be fitted in suction lines and straight taper reducers in

discharge and vertical lines. Undulations in the pipe runs are also to be avoided. Failure to comply with this

may cause the formation of air pockets in the piping and thus prevent the correct operation of the pump.

The suction pipe should be as short and direct as possible, and should be flushed clean before connecting

to the pump. Horizontal suction lines must have a gradual rise to the pump.

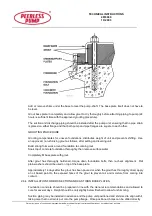

The discharge pipe is usually preceded by a non-return valve or check valve and a discharge gate valve.

The check valve is to protect the pump from excessive back pressure and reverse rotation of the unit and to

prevent back flow into the pump in case of stoppage or failure of the driver. The discharge valve is used in

priming, starting and when shutting down the pump.

FM FIREPUMP INSTALLATIONS (Loss Prevention Data 3-7N/13-4N)

Table 2-20

The diameter of the suction pipe, discharge pipe and gate valve should not be less than that

shown in the Table.

Para.3-1.2

The horizontal centrifugal fire pump in horizontal or vertical position should not be used

where a static suction lift is involved.

3.

OPERATION

3.1

BEFORE STARTING (After Installation or Maintenance)

Before initially starting the pump, make the following inspection:

The unit base plate must be grouted (where applicable), and bolted to the foundation.

Make sure all rotating parts are found to be free when turned by hand.

Ensure motor is correctly wired to its starting device.

Check that the voltage, phase and frequency

on the motor nameplate are correct for the line circuit.

Confirm correct direction of motor rotation prior to coupling to pump.

Check by starting motor and

switching off immediately, observing rotation is the same as the arrow direction on the pump casing.

Check the alignment between pump and motor.

Содержание HYF

Страница 2: ......