TECHNICAL INSTRUCTIONS

4853989

10/ 2003

Our policy is one of continuous improvement and we reserve the right to alter specifications of our products at any time.

- 9 -

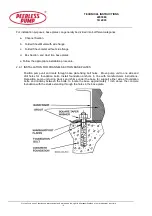

Add or remove shims under the base to level the pump-shaft of horizontally mounted pump units. The

base plate itself does not have to be level.

Torque down foundation nuts tight against the base plate and observe pump and motor shafts or

coupling hubs for alignment.

Note: Square tapered washers should be used on the channel section flanges, to ensure that the

foundation bolts are not bent.

Grout base plate in completely using non-shrink grout and allow it to dry thoroughly before attaching

piping to pump (24 hours is sufficient time with the approved grouting procedure).

The suction and discharge piping should be installed after the pump unit, ensuring that no pipe strain

is placed on either flange, and that both pump and pipe flanges are square to each other

GROUTING PROCEDURE

Grouting compensates for uneven foundations, distributes weight of unit and prevents shifting. Use

an approved, non-shrinking grout as follows:

Soak top of concrete foundation thoroughly, then remove surface water. Completely fill base plate

with grout.

After grout has thoroughly hardened check foundation bolts and re-tighten if necessary, then re-check

alignment.

Approximately 14 days after the grout has been poured or when the grout has thoroughly dried, apply

an oil based paint to the exposed faces of the grout to prevent air and moisture from coming into

contact.

2.6.2 INSTALLATION FOR FOLDED METAL BASE PLATES WITH SIDE FLANGES

Move pump unit into position and drill holes using base plate foundation holes as a guide. Install

anchors in line with manufacturers instructions. Use blocks and shims under the base for support,

either side of foundation bolts and midway between bolts, to raise the base approximately 1 inch

above the concrete foundation.

Содержание HYF

Страница 2: ......