27

Wireless Data Communication System - WD PRO Series Instruction Manual

7. Operation

40 mm

Strip 6 to 7 mm

Cut

(about 30 mm)

Terminal Block Connector

Body

Direct Mount

Bracket

Cable gland

Cap

Sealing plug

❷

❽

❺❼

❸

❻

❹

❶❾

(accessory)

(accessory)

(accessory)

7.1.1.1 Wiring RS-232C Cable from Bottom of Main Unit

40 mm

Strip 6 to 7 mm

Cut

(about 30 mm)

Terminal Block Connector

Body

Direct Mount

Bracket

Cable gland

Cap

Sealing plug

❷

❽

❺❼

❸

❻

❹

❶❾

(accessory)

(accessory)

(accessory)

☞ 7.1.3 Detaching the Terminal Block

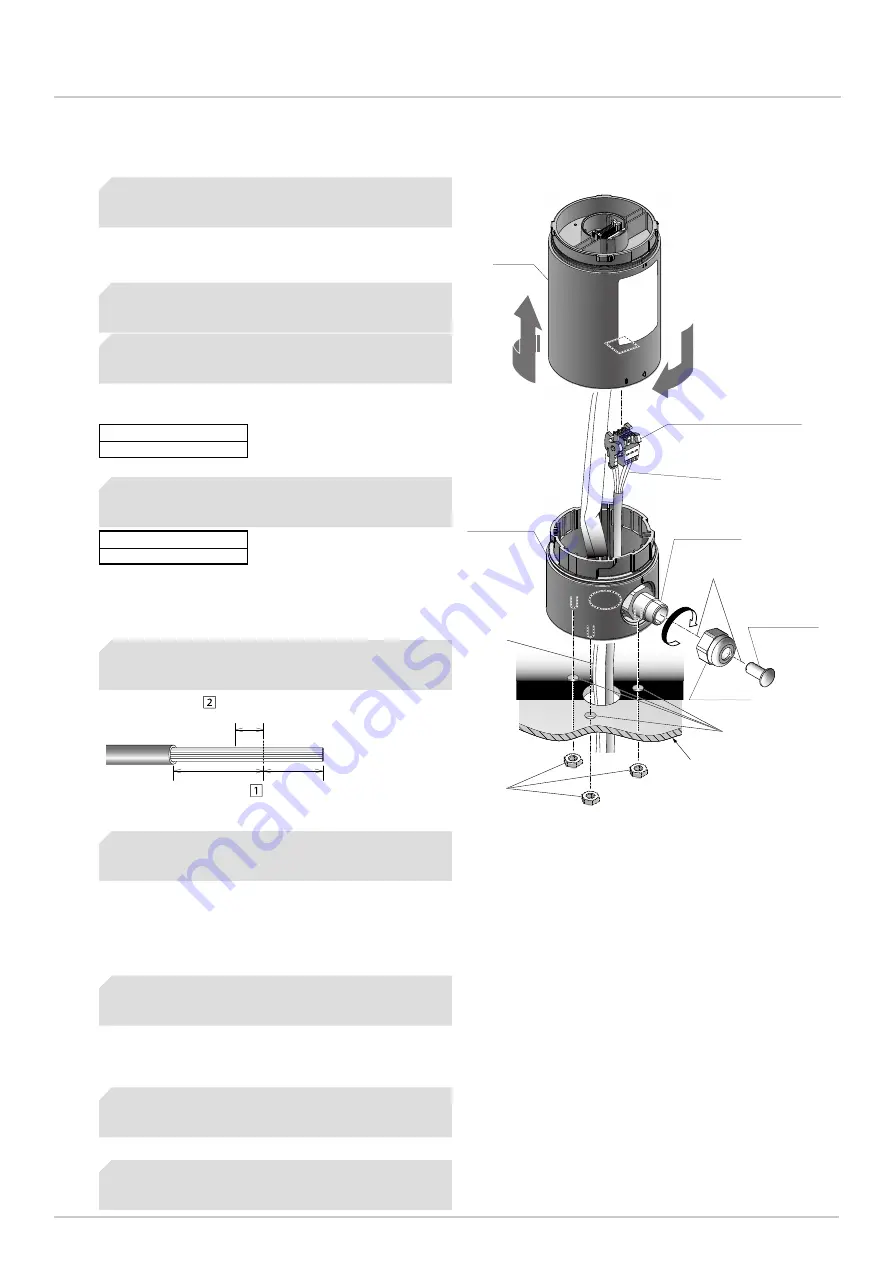

In the mounting location, drill holes for mounting

and wiring the product.

❶

Rotate the body counterclockwise and detach

from the direct mount bracket.

❷

Apply the sealing plug and cap to the cable

gland, and rotate the cap clockwise to attach.

❸

Use nuts to secure the direct mount bracket in

the mounting position.

❹

Cut the RS-232C cable's lead wires so 40 mm

remains, then strip them.

❺

Pass the wires (gray or black) and RS-232C

cable through the wire distribution hole.

❻

Wire the RS-232C cable to the terminal block

connector and attach to the body.

❼

Attach the body to the direct mount bracket,

reversing the steps for detaching.

❽

If required, apply sealant around the mounting

and wire distribution holes.

❾

* When the sealing plug pops out of the cap, use your

hand to push the sealing plug back in.

* This illustration presents an overview of installation and

does not reflect the installation status at each step.

* RS-232C cable is not included.

* Maximum board

thickness: 7 mm.

☞ Mounting Hole Dimension Diagram(P.25)

* When using a pole bracket and pole, drilling holes is

unnecessary.

* When using a pole bracket and pole, refer to “7.1.1.4

Wiring Method When Using Pole Bracket and Pole

Recommended Torque

0.6 N•m (approximate)

Recommended Torque

0.6 N•m (approximate)

☞ 7.1.2 Replacing Mounting Bolts (M4 → M3) on the

* Do not secure when using a pole bracket and pole.