13

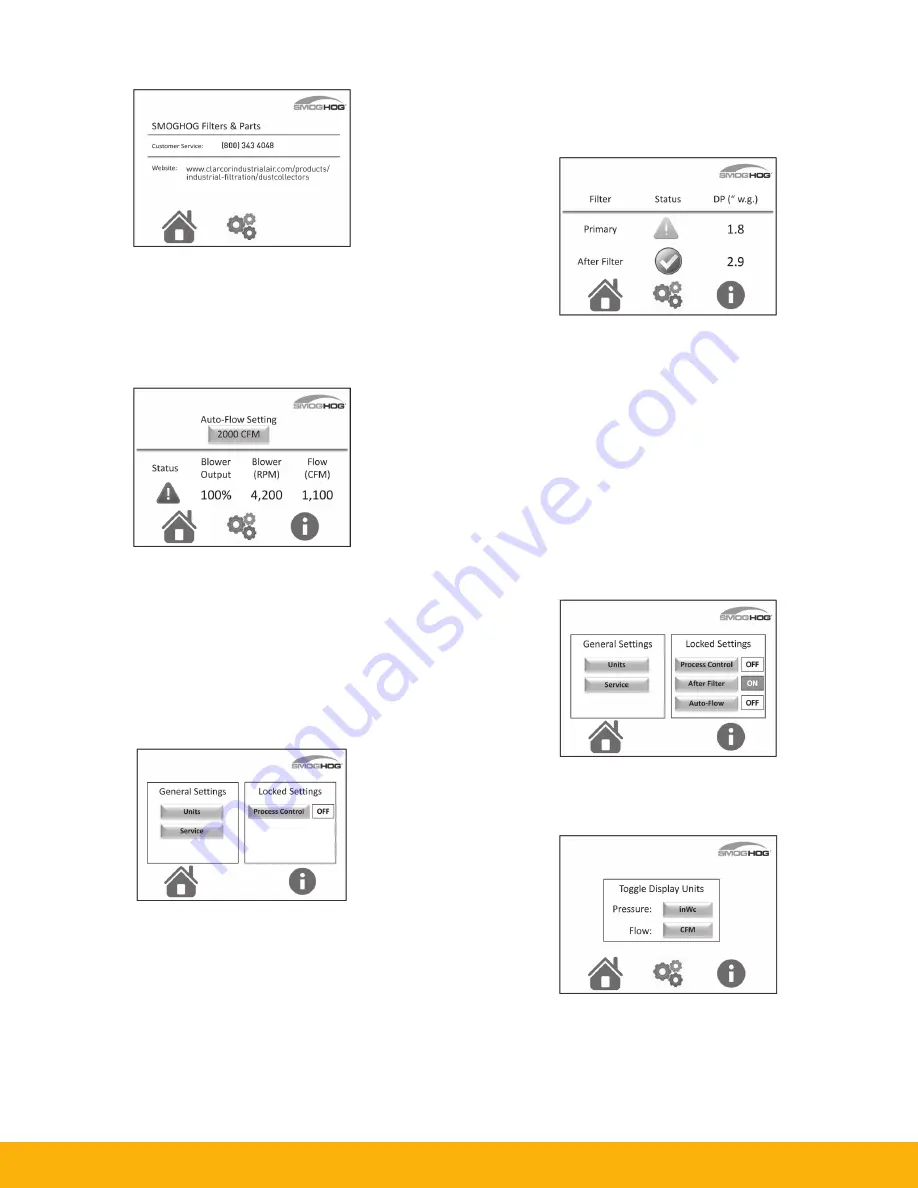

Information Screen:

Figure 9

The information screen will provide a phone number for customer

service. There is also a web address for our website that can be

used to locate your nearest representative.

4.3.4 Auto-Flow Screen

Figure 10

When Auto-Flow is installed and activated the blower screen will

look like Figure 10. Refer to section 4.3.6 to activate the Auto-

Flow option and to make adjustments to your flow target. The

Auto-Flow blower screen will show the target flow, the actual

flow, the blower speed, and the % of total speed available. The

screen will also show blower status. If there is a warning or fault,

refer to the troubleshooting section for guidance.

4.3.5 After-Filter

Figure 11

When the screen is active you will see the differential pressure

across the filter. The system will monitor this pressure and give

warnings and faults as the differential pressure changes. The

after-filter does not get cleaned by the system and has a finite life

based on the pressure drop across the filter. When the pressure

drop increases to a point that the filter can no longer provide

proper airflow, the fault symbol will appear. You will need to

replace the filter at that time.

4.3.6 Customer Settings

The standard customer settings screen shown in Figure 12 will allow

the operator to make General Settings changes without a password.

The Locked Settings will require a password to be entered. The

default password is 4440.

Figure 12

The General Settings selection will allow the operator to change

the units and check service of the major components like the

blower. These settings are not password protected. To select one

of the items just touch the box with the item you want to make

a change too.

The Locked Settings selection will allow the operator to select

options of the system. One option is Machine Interlock. With

Machine Interlock the operator can allow another device (CNC

machine center, plasma table, or weld machine) to turn the SHM

on when the primary device is in operation. When this option is

selected (see Figure 20) the Blower Power button in Figure 6 will

put the unit in standby when touched by the operator. When this

setting is selected the indicator to the right side will change from

OFF to ON and turn green.

Figure 13

When After-Filter and/or Auto-Flow options are ordered, they will

appear on the Customer Settings screen as shown on Figure 13.

Figure 14

When the units selection is made on the Customer Settings

screen, you will see the screen as shown on Figure 14.

Содержание SmogHog SHM-C

Страница 1: ...SMOG HOG Media Mist Collector Owner s Manual Models SHM C SHM F...

Страница 6: ...Page intentionally left blank...

Страница 8: ...4 FIGURE 1B SHM Equipment Description 61 10113 FIGURE 1A SHM Equipment Description...

Страница 13: ...9 61 10126 FIGURE 4 Remote Panel Touchscreen Connection...

Страница 15: ...11 61 10115 FIGURE 5B SHM Filter Removal Installation FIGURE 5A SHM Filter Removal Installation...

Страница 23: ...19 Figure 6 SHM Replacement Parts SHM 11C SHM 11F...

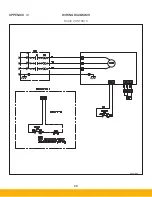

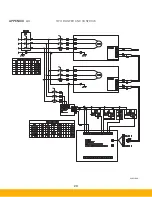

Страница 24: ...20 APPENDIX A1 WIRING DIAGRAMS BASIC CONTROLS 04 001682...

Страница 25: ...21 REMOTE PANEL BASIC CONTROLS 04 001799 APPENDIX A2...

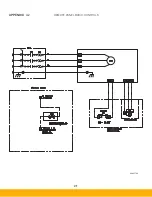

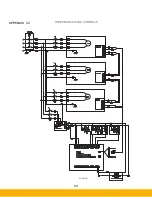

Страница 26: ...22 ONE BLOWER AND CONTROLS 04 001695 APPENDIX A3...

Страница 27: ...23 TWO BLOWER AND CONTROLS 04 001696 APPENDIX A4...

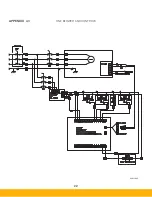

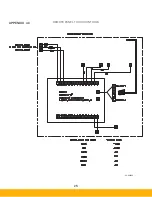

Страница 28: ...24 THREE BLOWER AND CONTROLS 04 001697 APPENDIX A5...

Страница 29: ...25 REMOTE PANEL TOUCH CONTROLS 04 001802 APPENDIX A6...

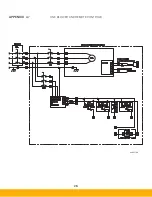

Страница 30: ...26 ONE BLOWER AND REMOTE CONTROLS 04 001798 APPENDIX A7...

Страница 31: ...27 TWO BLOWER AND REMOTE CONTROLS 04 001797 APPENDIX A8...

Страница 32: ...28 THREE BLOWER AND REMOTE CONTROLS 04 001796 APPENDIX A9...

Страница 33: ...29 575 480 TRANSFORMER 04 001717 APPENDIX A10...

Страница 36: ...32...

Страница 37: ...33...