5.1 General Maintenance Guidelines

Proper maintenance of the SHM is essential for the unit to provide

excellent oil mist collection capabilities and long-term service. By

keeping the unit well-maintained, you will also reduce operating and

parts replacement costs. A scheduled preventive maintenance

program, specifically designed for the SHM and its associated

components, is the best possible method to ensure the unit stays

in proper working order.

Refer to Section 6 for troubleshooting guide to correct any problems

that may occur with your oil mist collection unit. If the problem or

condition continues, contact Parker customer service for assistance.

5.2 Filter Service

Automatic filter replacement warnings should display on units so

equipped.

On unequipped units, when the primary filters reach the point

of not being able to maintain proper unit function they must be

replaced.

To order filters, contact your Parker sales representative. Identify

your filter part number from your sales order, your unit nameplate,

or the inside cover of this manual.

The aluminum mesh pre-filter can be washed and rinsed with a

moderately powerful spray from a power-washer or hose. This filter

can be replaced if contaminants become impossible to remove or

due to excessive wear.

Always wear proper PPE including goggles, dust

mask and work gloves when installing or replacing

filter elements. Oil accumulated on the filter ele-

ments can result in irritation of the lungs, skin, and

/ or eyes.

5.2.1 Installation procedure for PEACH

saturated depth filter elements

Inspect filters to verify there is no damage and all packing materials

have been removed. A supportive piece of foam may be inside the

filter tube and should be removed before operation. Be careful upon

removal not to pull too aggressively to dislodge the inner-most end cap.

Set the header plate (balloon #3 in Figure 5A) on the floor and place a

cartridge in the center of each hole. Lift the header plate up until the top

flange of each cartridge rests on the plate. Slide the filter assembly onto

the cam-bar and into the cabinet while the cam-bar is in the lowered

position (balloon #4 in Figure 5A) (both handles down) until the filter

bottoms out on a stop. Once the entire cassette is inserted into the

cabinet verify that each filter is sitting straight and fully seated in each

header plate hole.

Rotate the cam-bars upward as illustrated in balloon #5 to push the

filter up and seal it against the tube sheet.

!

D A N G E R

Task

Maintenance Interval

Check Sump Level, Verify Proper Drainage Weekly (increased frequency may be necessary)

Check For Accumulated Material

Monthly (or when filters are replaced or bin emped)

*Add to this list and adjust the maintenance interval as necessary based on applicaon.

TABLE 4

Maintenance Schedule

Remove used filter elements from the collector and dispose of

properly, in accordance with governing restrictions. Be sure there

is no excess oil or residue build-up inside the primary filter cabinet.

Clean or rinse as necessary. Inspect all filter sealing cam bars and

filter support parts for unusual signs of wear or failure. Checking all

gaskets and seals is recommended at this time, as well as replace-

ment if necessary.

The surface of the filter element can be damaged as a result of improp-

er moving or handling. Care must be taken to prevent any damage to

the filter media.

Inspect each filter element for damage from shipping, storage or han-

dling. Do not use damaged elements, they may leak or fail prematurely.

Review installation procedures for filter elements before beginning the

installation procedures and accessing the oil mist collector. Follow the

proper lockout, tagout procedures.

5. Service

Before servicing equipment:

• Wear appropriate protective equipment when

servicing oil mist collector.

• Disconnect and lockout electrical power to the

unit and control panel.

C A U T I O N

15

Содержание SmogHog SHM-C

Страница 1: ...SMOG HOG Media Mist Collector Owner s Manual Models SHM C SHM F...

Страница 6: ...Page intentionally left blank...

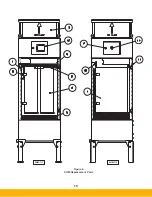

Страница 8: ...4 FIGURE 1B SHM Equipment Description 61 10113 FIGURE 1A SHM Equipment Description...

Страница 13: ...9 61 10126 FIGURE 4 Remote Panel Touchscreen Connection...

Страница 15: ...11 61 10115 FIGURE 5B SHM Filter Removal Installation FIGURE 5A SHM Filter Removal Installation...

Страница 23: ...19 Figure 6 SHM Replacement Parts SHM 11C SHM 11F...

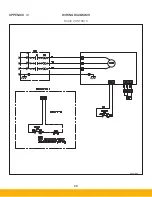

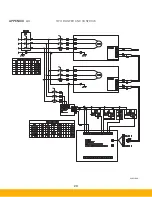

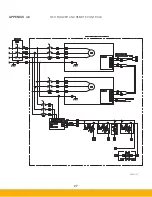

Страница 24: ...20 APPENDIX A1 WIRING DIAGRAMS BASIC CONTROLS 04 001682...

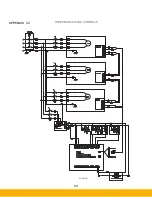

Страница 25: ...21 REMOTE PANEL BASIC CONTROLS 04 001799 APPENDIX A2...

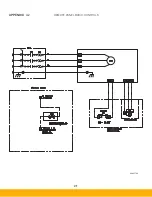

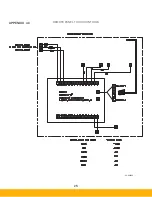

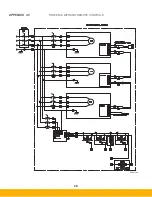

Страница 26: ...22 ONE BLOWER AND CONTROLS 04 001695 APPENDIX A3...

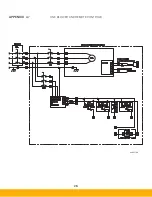

Страница 27: ...23 TWO BLOWER AND CONTROLS 04 001696 APPENDIX A4...

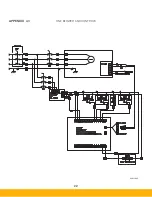

Страница 28: ...24 THREE BLOWER AND CONTROLS 04 001697 APPENDIX A5...

Страница 29: ...25 REMOTE PANEL TOUCH CONTROLS 04 001802 APPENDIX A6...

Страница 30: ...26 ONE BLOWER AND REMOTE CONTROLS 04 001798 APPENDIX A7...

Страница 31: ...27 TWO BLOWER AND REMOTE CONTROLS 04 001797 APPENDIX A8...

Страница 32: ...28 THREE BLOWER AND REMOTE CONTROLS 04 001796 APPENDIX A9...

Страница 33: ...29 575 480 TRANSFORMER 04 001717 APPENDIX A10...

Страница 36: ...32...

Страница 37: ...33...